Double sided pcb Normal pcb Lead free HASL Counterbore Manufacturer | YMS PCB

HAL(Lead Free), the full name is Hot Air leveling with Lead Free. Compared with HASL, the main difference for HAL(Lead Free) is the element of material which do not contain Lead(Pb), so it’s RoHS Compliant and it’s much more popular and widely used in ПХБ -ийн үйлдвэрлэлийн .

HAL(Lead Free) requires higher run temperatures for lead free solder and longer contact time, the production cost for HAL(Lead Free) is slightly higher than HASL(Tin/Lead).

The manufacturing process of HAL(Lead Free) is similar to HASL(Tin/Lead), the circuit boards will be submersed in molten solder(Lead Free). This solder will cover all the exposed copper surfaces. Upon retraction from the solder, high pressure hot air is blown over the surface through air knives, this levels the solder deposit and removes the excess solder from the surface of printed circuit boards.

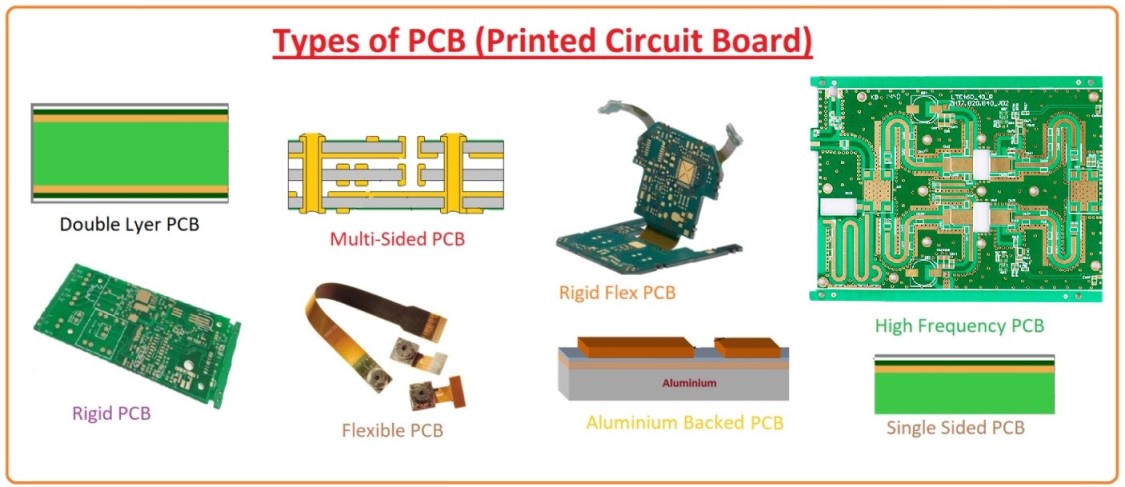

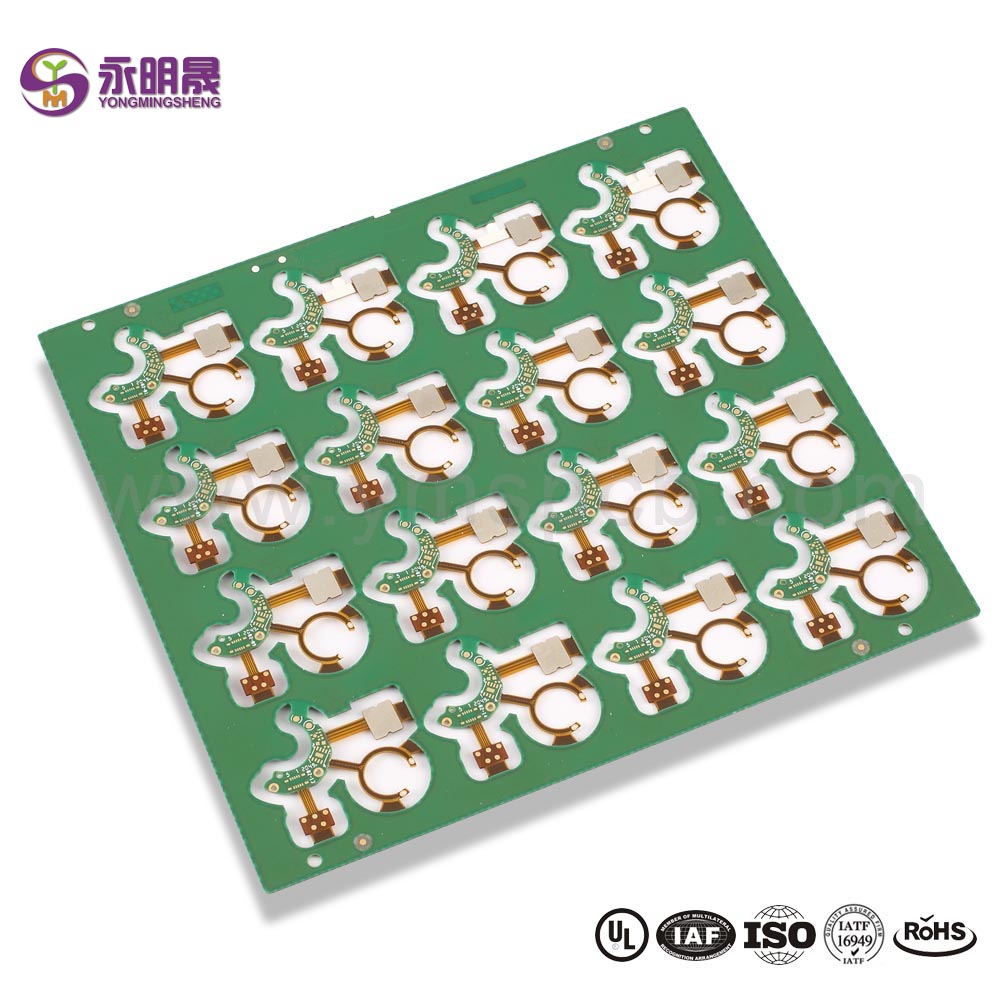

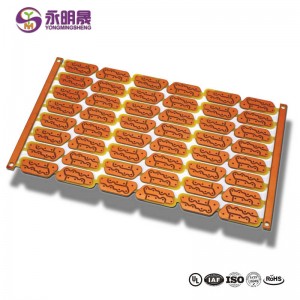

Хэвлэмэл хэлхээний самбарын танилцуулга

Хэвийн хэвлэмэл хэлхээний самбар: Most PCBs for simple electronics are simple and composed of only a single layer. More sophisticated hardware such as computer graphics cards or motherboards can have 2 or multiple layers, sometimes up to twelve.

A printed circuit board (PCB) mechanically supports and electrically connects electrical or electronic components using conductive tracks, pads and other features etched from one or more sheet layers of copper laminated onto and/or between sheet layers of a non-conductive substrate. Components are generally soldered onto the PCB to both electrically connect and mechanically fasten them to it.PCBs can be single-sided (one copper layer), double-sided (two copper layers on both sides of one substrate layer), or multi-layer (outer and inner layers of copper, alternating with layers of substrate). Multi-layer PCBs allow for much higher component density, because circuit traces on the inner layers would otherwise take up surface space between components. The rise in popularity of multilayer PCBs with more than two, and especially with more than four, copper planes was concurrent with the adoption of surface mount technology.

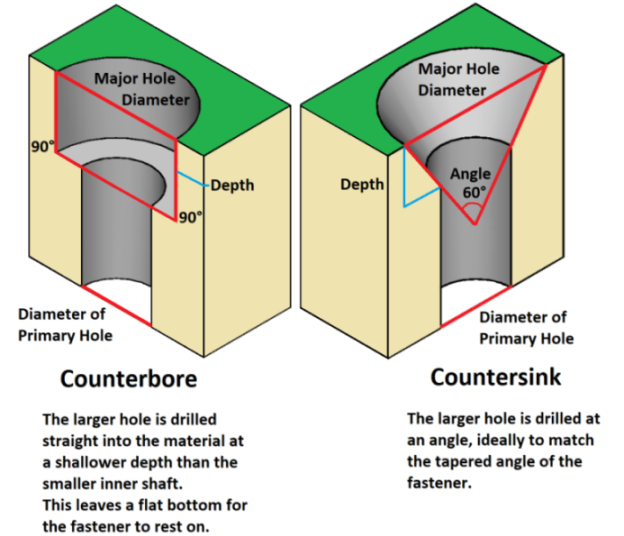

What is the difference between a Countersink and a Counterbore?

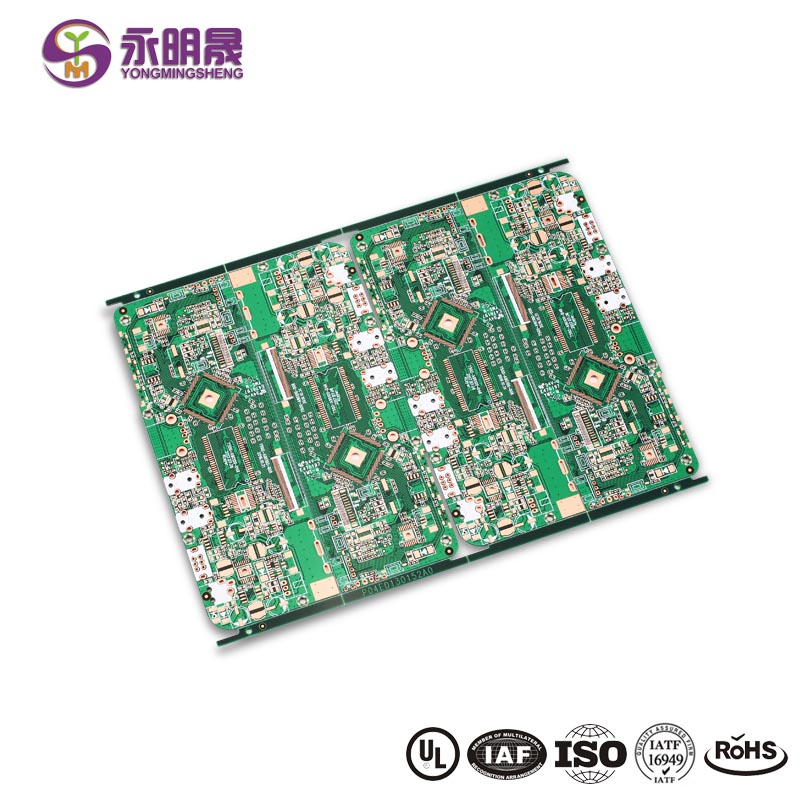

YMS хэвийн ПХБ-ийн үйлдвэрлэлийн чадвар:

| YMS Хэвийн ПХБ-ийн үйлдвэрлэлийн чадавхийн тойм | ||

| Онцлог шинж чанар | чадвар | |

| Давхаргын тоо | 1-60л | |

| Хэвийн ПХБ-ийн технологи ашиглах боломжтой | 16: 1 харьцаатай нүхээр дамжина | |

| оршуулсан ба сохор | ||

| Эрлийз | RO4350B, FR4 Mix гэх мэт өндөр давтамжийн материал. | |

| M7NE, FR4 Mix гэх мэт өндөр хурдны материал. | ||

| Материал | CEM- | CEM-1; CEM-2 ; CEM-4 ; CEM-5. гэх мэт |

| FR4 | EM827, 370HR, S1000-2, IT180A, IT158, S1000 / S1155, R1566W, EM285, TU862HF, NP170G гэх мэт. | |

| Өндөр хурдны | Megtron6, Megtron4, Megtron7, TU872SLK, FR408HR, N4000-13 Series, MW4000, MW2000, TU933 гэх мэт. | |

| Өндөр давтамж | Ro3003, Ro3006, Ro4350B, Ro4360G2, Ro4835, CLTE, Genclad, RF35, FastRise27 гэх мэт. | |

| Бусад | Полимид, Tk, LCP, BT, C-ply, Fradflex, Omega, ZBC2000, PEEK, PTFE, керамик суурьтай гэх мэт. | |

| Зузаан | 0.3-8 мм | |

| Зэсийн зузаан | 10 унц | |

| Хамгийн бага мөрийн өргөн ба зай | 0.05mm / 0.05mm (2mil / 2mil) | |

| BGA PITCH | 0.35 мм | |

| Хамгийн бага механик өрөмдлөгийн хэмжээ | 0.15мм (6мл) | |

| Нүхний харьцаа | 16: 1 | |

| Гадаргуугийн өнгөлгөө | HASL, хар тугалгагүй HASL, ENIG, Immersion Tin, OSP, Immersion Silver, Gold Finger, Electroplate Hard Gold, Selective OSP , ENEPIG.etc. | |

| Дүүргэх сонголтоор | Дамжуулагчийг өнгөлж, дамжуулагч эсвэл дамжуулагч бус эпоксидоор дүүргээд дараа нь таглаад (VIPPO) бүрнэ. | |

| Зэс дүүрсэн, мөнгө дүүрсэн | ||

| Бүртгэл | ± 4 миль | |

| Гагнуурын маск | Ногоон, улаан, шар, цэнхэр, цагаан, хар, нил ягаан, царцсан хар, царцсан ногоон гэх мэт. | |

Танд таалагдах боломжтой:

1、Summary of matters needing attention in circuit board welding

4、Нүцгэн самбарын туршилт гэж юу вэ?

5. Өндөр давтамжийн ПХБ дизайн гэж юу вэ

YMS бүтээгдэхүүний талаар илүү ихийг олж мэдэх