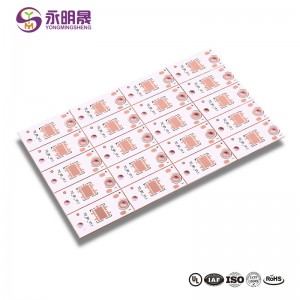

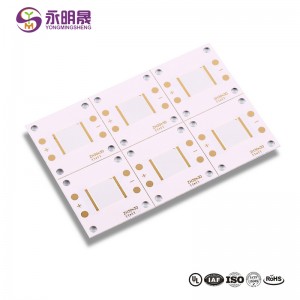

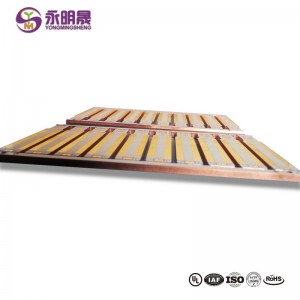

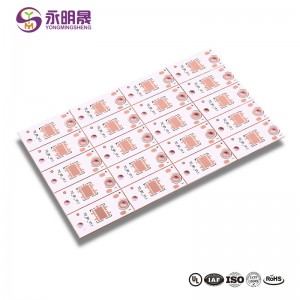

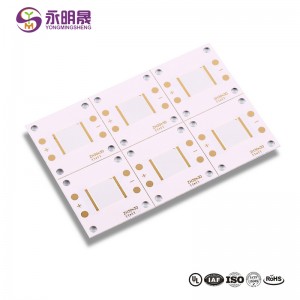

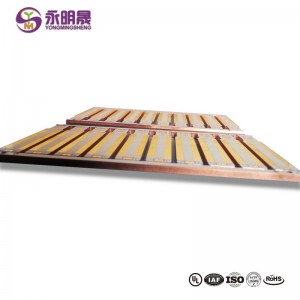

Metal core PCB, known for their ability to provide effective thermal dissipation for electronic products), is the most common type – the base material consists of Metal core with standard FR4. It features a thermal clad layer that dissipates heat in a highly efficient manner, while cooling components and increasing the overall performance of the products. Currently, Metal Backed PCBs is regarded as the solution to high power and tight tolerance applications.

Through long term research and study, and accumulated years of experience,we mastered the high-end technology of Metal PCB.

1.Multi laminating aluminum-based PCBs / Soldering technology to cooper-base PCBs fulfill the needs of better heat radiating on multi-layer PCBs;

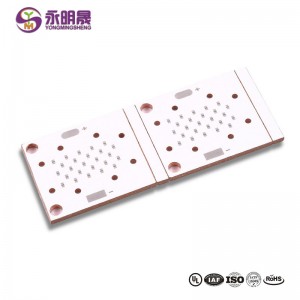

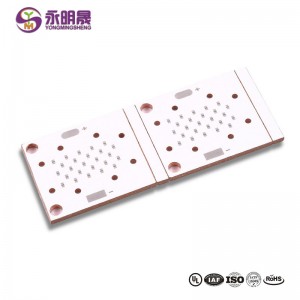

2.Buried magnetic core technology for metal-based PCBs with metal laminates in the middle enables heat radiating and also small size integration;

3.The technology of partially buried copper fulfills the needs of cost saving, small size integration and high radiating;

4.The design capability of concentric circles in metal base PCBs enables the isolation between fix holes and PTH holes in those PCBs;

5.The integrated coursing technology in metal base PCBs ensures the high reliability between metal base and epoxy resin or hydrocarbon laminates.