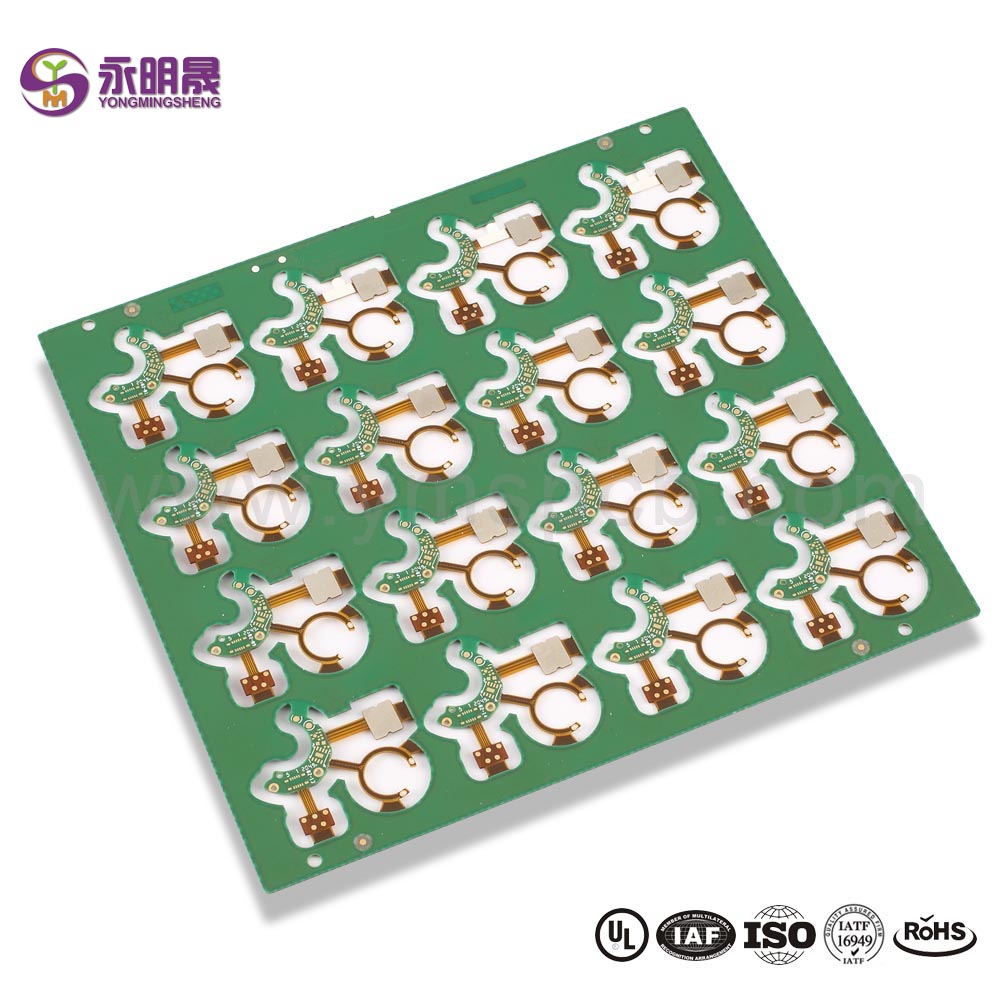

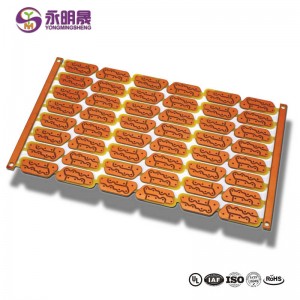

Double sided pcb Normal pcb Lead free HASL Counterbore Manufacturer | YMS PCB

HAL(Lead Free), the full name is Hot Air leveling with Lead Free. Compared with HASL, the main difference for HAL(Lead Free) is the element of material which do not contain Lead(Pb), so it’s RoHS Compliant and it’s much more popular and widely used in PCB Produktiounsfäegkeeten .

HAL(Lead Free) requires higher run temperatures for lead free solder and longer contact time, the production cost for HAL(Lead Free) is slightly higher than HASL(Tin/Lead).

The manufacturing process of HAL(Lead Free) is similar to HASL(Tin/Lead), the circuit boards will be submersed in molten solder(Lead Free). This solder will cover all the exposed copper surfaces. Upon retraction from the solder, high pressure hot air is blown over the surface through air knives, this levels the solder deposit and removes the excess solder from the surface of printed circuit boards.

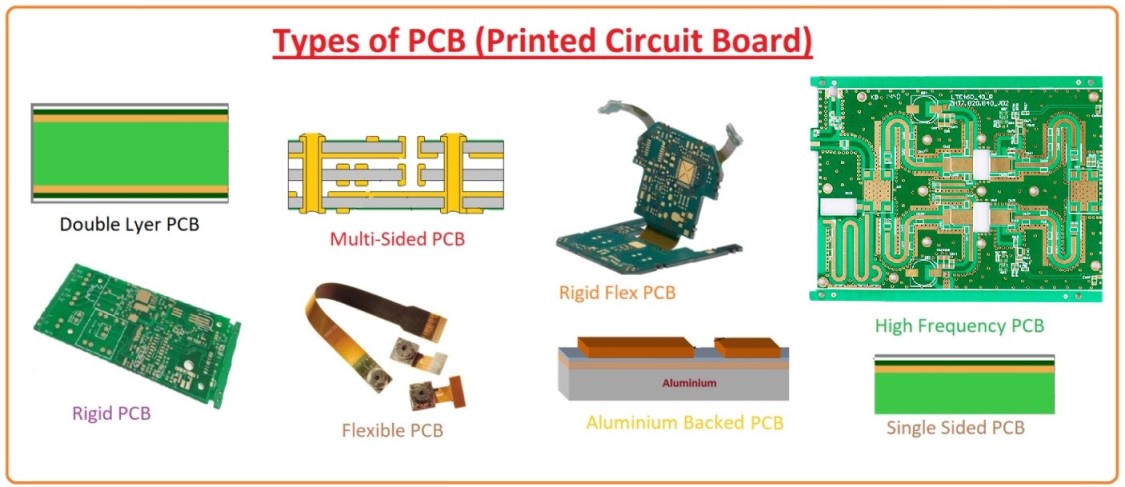

Gedréckt Circuit Board Aféierung

Normal gedréckt Circuit Verwaltungsrot: Most PCBs for simple electronics are simple and composed of only a single layer. More sophisticated hardware such as computer graphics cards or motherboards can have 2 or multiple layers, sometimes up to twelve.

A printed circuit board (PCB) mechanically supports and electrically connects electrical or electronic components using conductive tracks, pads and other features etched from one or more sheet layers of copper laminated onto and/or between sheet layers of a non-conductive substrate. Components are generally soldered onto the PCB to both electrically connect and mechanically fasten them to it.PCBs can be single-sided (one copper layer), double-sided (two copper layers on both sides of one substrate layer), or multi-layer (outer and inner layers of copper, alternating with layers of substrate). Multi-layer PCBs allow for much higher component density, because circuit traces on the inner layers would otherwise take up surface space between components. The rise in popularity of multilayer PCBs with more than two, and especially with more than four, copper planes was concurrent with the adoption of surface mount technology.

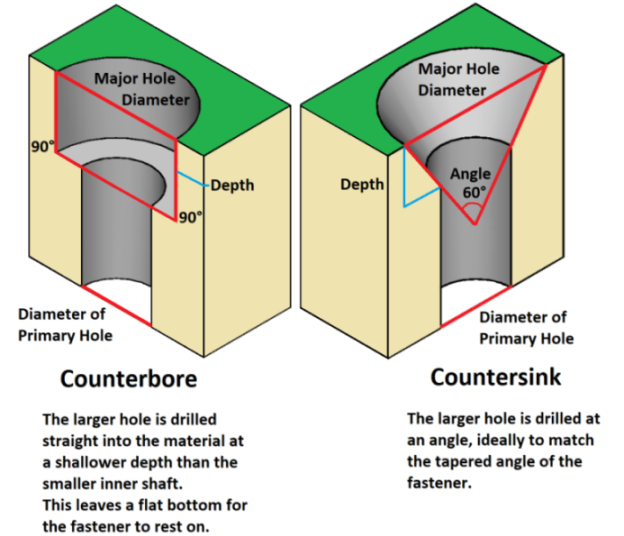

What is the difference between a Countersink and a Counterbore?

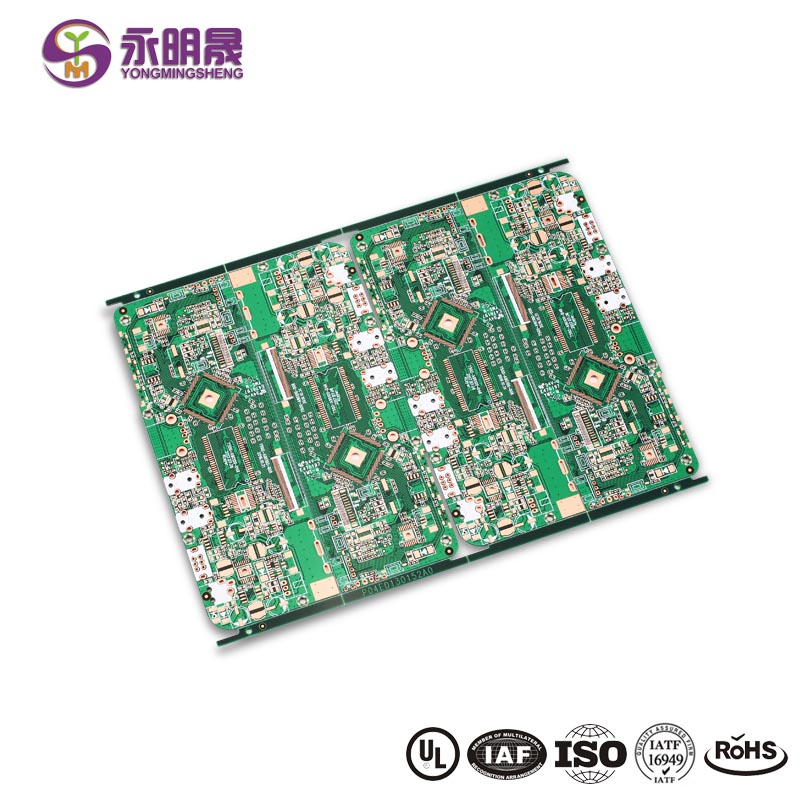

YMS Normal PCB Fabrikatiounsméiglechkeeten:

| YMS Normal PCB Fabrikatiounsfäegkeeten Iwwersiicht | ||

| Fonktioun | Fäegkeeten | |

| Schicht Grof | 1-60 l Eng | |

| Verfügbar Normal PCB Technologie | Duerch Lach mat Aspekt Verhältnis 16: 1 | |

| begruewen a blann via | ||

| Hybrid | Héich Frequenzmaterial wéi RO4350B a FR4 Mix etc. | |

| High Speed Material wéi M7NE a FR4 Mix etc. | ||

| Material | CEM- | CEM-1; CEM-2, CEM-4, CEM-5. asw |

| FR4 | EM827, 370HR, S1000-2, IT180A, IT158, S1000 / S1155, R1566W, EM285, TU862HF, NP170G etc. | |

| Heichgeschwindegkeet | Megtron6, Megtron4, Megtron7, TU872SLK, FR408HR, N4000-13 Serie, MW4000, MW2000, TU933 etc. | |

| héich Heefegkeet | Ro3003, Ro3006, Ro4350B, Ro4360G2, Ro4835, CLTE, Genclad, RF35, FastRise27 etc. | |

| Anerer | Polyimid, Tk, LCP, BT, C-ply, Fradflex, Omega, ZBC2000, PEEK, PTFE, Keramikbaséiert etc. | |

| Déck | 0,3 mm-8 mm | |

| Max.Kupfer Déck | 10 OZ | |

| Minimum Linn Breet a Weltraum | 0.05mm / 0.05mm (2mil / 2mil) | |

| BGA PITCH | 0,35mm | |

| Min mechanesch Boormooss | 0.15mm (6mil) | |

| Aspekt Verhältnis fir duerch Lach | 16 : 1 | |

| Uewerfläch fäerdeg | HASL, Bläifräien HASL, ENIG, Immersion Tin, OSP, Immersion Silver, Gold Finger, Galvaniséierung Hard Gold, Selektiv OSP , ENEPIG.etc. | |

| Iwwer Fill Optioun | De via gëtt plated a mat entweder leitend oder net-leitend Epoxy gefëllt, duerno ofgedeckt a plated (VIPPO) | |

| Kupfer gefëllt, sëlwer gefëllt | ||

| Umeldung | ± 4mil | |

| Solder Mask | Gréng, Rout, Giel, Blo, Wäiss, Schwaarz, Purpur, Matt Schwaarz, Matt Gréng. | |

Dir kënnt Wéi:

1, Summary of matters needing attention in circuit board welding

3, What is PCB

Léiert méi iwwer YMS Produkter