Flex rigid Board semi flex PCB Black Soldermask| YMSPCB

What is Semi-Flex PCB?

Maxime traditional vestibulum processus de semi-LENTO PCB capiatve flexuram US-IV materiae et faciens PCB secundum traditional rigidum PCB manufacturing processus, et per alta milling technology ad tenues locis esse opus, ut flectantur, ita quod non habet mollitiem quandam ut metus tendentes circa conventus.

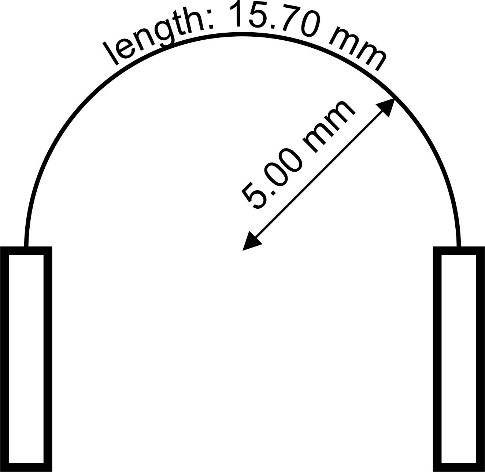

SEMI-LENTO longitudinem Calculatorium: (x II Π manum radii x) x (flexuram angulus / CCCLX °)

Nam ista CLXXX gradus angulus V radius interdum eget 5mm minima parte semi-flex 15,7mm

YMS Semi-LENTO PCB faciens capa capacitatem capam;

| YMS Semi-LENTO PCB vestibulum elit Overview | ||

| feature | facultatem | |

| stratum comitis | 2-20L et I - II, in PROLIXUS partis sectione flexibile | |

| Seu Rigidorum VOL Crassitudine-LENTO | 0.5mm, 5.0mm | |

| PCB crassitudine sectionem in flex | 0.15-0.8mm ± 0.05mm | |

| Crassitudo aeris | I / 4oz 10OZ, | |

| Vivamus ipsum aciem spatium minimum | 0.05mm / 0.05mm (2mil / 2mil) | |

| stiffeners | Aliquam ferro, P. I, FR4 Aluminium etc. | |

| material | FR4 RA aeris, aeris HTE, tenaces: Bondply, coverlayer, flex soldermask | |

| Min Location mechanica Drilled | 0.15mm (6mil) | |

| Laser egréssus min Size: | 0.075mm (3mil) | |

| Conclusio superficiem | Proin idoneam / M. PCB urface ratio exigit: Electroless Nickel: Aurum immersionis, ENEPIG, removerit Category: immersionis Silver.etc. | |

| Os solidaturam | Viridis, Red, Yellow, cæruleus, albus, Nigrum, Purple, Matte Nigrum, Matte green.etc. | |

| Covrelay (LENTO Part) | Yellow Coverlay, WhiteCoverlay: Nigrum Coverlay |

|

Disce de products YMS

Read more news

What is a rigid flex board?

The rigid-flex board is a flexible circuit board(FPC) and a rigid circuit board (PCB), which are combined together according to the relevant process requirements through pressing and other processes in the PCB proofing to form a circuit board with FPC characteristics and PCB characteristics.

What is difference between rigid and flexible boards?

As the names suggest, a rigid PCB is a circuit board built on a rigid base layer that cannot bend, while a flexible PCB, also called a flex circuit, is built on a flexible base capable of bending, twisting and folding.

Where are rigid flex PCBs used?

You’ll find them in commercial, industrial and military applications. From digital cameras to cell phones to smart devices, they serve them all. Especially in the medical industry for developing pacemakers for their weight reduction, space, and flexible capabilities.