Flexible Circuit Board Supplier-Fast Delivery | YMSPCB

Cost Effective Flex & Rigid-Flex PCBs

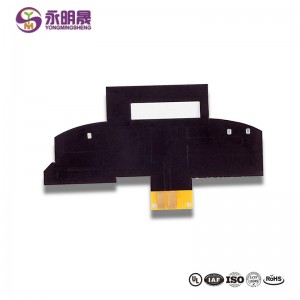

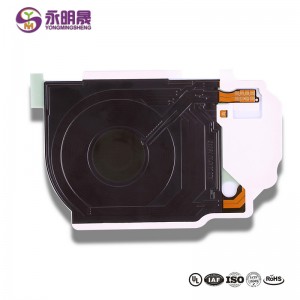

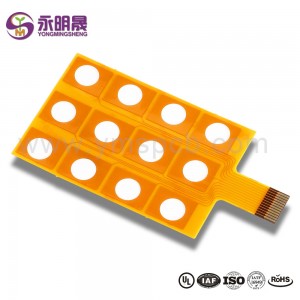

When it comes to our flex and rigid-flex products, we offer a variety of cost effective solutions and capabilities that include single or double sided circuitry to higher technology multilayer designs up to 20 layers. From selecting the best functional configuration, to choosing the proper connectors or components, we will help you meet or exceed all your applications requirements.

Our flex and rigid-flex PCBs are manufactured for various applications in the medical, military, aerospace, and portable devices industries.

Our engineering team can assist you from early design stages of your application all the way to end product production for all your flex and rigid-flex circuit needs.

Flex & Rigid-Flex PCB Manufacturing Lead Times

It's important to note that all lead times are technology dependent.

Flex:1-10 days (2-week standard lead)

Multilayer Flex (3-6 layers):2-15 days (3-week standard lead)

Multilayer flex (8-30 layers):7-20 days

Rigid-flex (2-6 layers):5-15 days (3-week standard lead)

Rigid-flex (8-30 layers):7-20 days

| 특색 | Capability |

| Quality Grade | Standard IPC 2 |

| Number of Layers | 1 - 8layers |

| Order Quantity | 1pc - 10000+pcs |

| Build Time | 2days - 5weeks |

| 재료 | DuPont PI, Domestic Shengyi PI |

| Board Size | Min 6*6mm, Max 406*610mm |

| 보드 두께 | 0.1mm - 0.8mm |

| Copper Weight (Finished) | 0.5oz - 2.0oz |

| Min Tracing/Spacing | 3mil/3mil |

| Solder Mask Sides | As per the file |

| Solder Mask Color | Green, White, Blue, Black, Red, Yellow |

| Solder-stop coating---Soldermask oil | Green, White, Blue, Black, Red, Yellow |

| Solder-stop coating---Coverlay | PI and PET film |

| Silkscreen Sides | As per the file |

| Silkscreen Color | White, Black, Yellow |

| 표면 마감 | HASL - Hot air solder leveling Lead - free HASL - RoHS ENIG - RoHS Immersion Tin - RoHS OSP - RoHS |

| Min Annular Ring | 4mil |

| Min Drilling Hole Diameter | 8mil |

| Min. hole size---Drilling (PTH) | 0.2mil |

| Min. hole size---Punching (NPTH) | 0.5mil |

| Tolerance of dimension | ±0.05mm |

| Other Techniques | Peelable solder mask Gold fingers Stiffener (only for PI/FR4 substrate) |

Our High-Quality Flexible PCB Manufacturing Process

A key reason why YMS is widely regarded as a top PCB factory is our unwavering commitment to quality. Our experienced team checks each design and takes the time to review it with you prior to production. This ensures the circuit design is ready for manufacturing, and your boards will deliver the performance you expect. We guarantee the quality of our flex PCB parts and components.

동영상

회로 기판은 유연할 수 있습니까?

네

연성 회로는 무엇에 사용됩니까?

LCD 텔레비전, 휴대폰, 안테나, 노트북 등에 널리 사용되고 있습니다! 이러한 통신 장치는 플렉스 PCB의 출현으로 비약적인 발전을 보였습니다. 그러나 플렉스 회로의 사용은 여기에만 국한되지 않습니다.

PCB를 유연하게 만들려면 어떻게 해야 합니까?

1단계: 구리 코팅 필름을 얻습니다.

2단계: 단색 잉크 프린터를 사용합니다.

3단계: Pyralux에서 인쇄

4단계: 에칭

5단계: 보드 채우기