HDI pcb sembarang lapisan hdi pcb tes kecepetan kecepetan tes enepig | YMSPCB

Apa HDI PCB

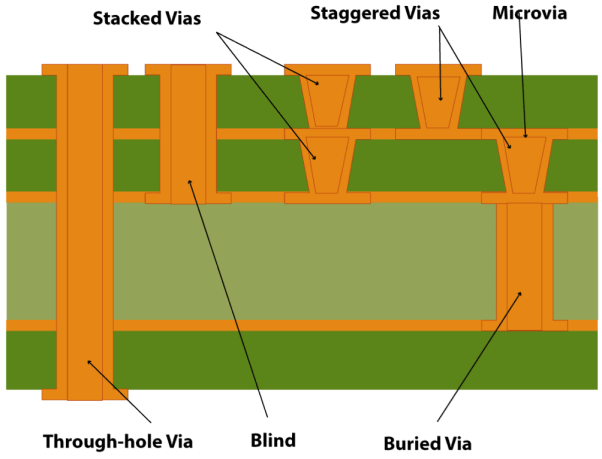

PCB HDI Kab: High density interconnect PCB, are a way of making more room on your printed circuit board to make them more efficient and allow for faster transmission. It's relatively easy for most enterprising companies that are using printed circuit boards to see how this can benefit them.

Kaluwihan HDI PCB

Alesan sing paling umum nggunakake teknologi HDI yaiku nambah kapadhetan kemasan. Ruang sing dipikolehi kanthi struktur trek sing luwih apik kasedhiya kanggo komponen. Kajaba iku, syarat ruang umume dikurangi bakal nyebabake ukuran papan sing luwih cilik lan lapisan luwih sithik.

Biasane FPGA utawa BGA kasedhiya kanthi jarak 1mm utawa kurang. Teknologi HDI nggawe gampang nuntun lan nyambungake, utamane nalika nuntun ing antarane pin.

YMS HDI PCB manufaktur :

| Ringkesan kabisan pabrik YMS HDI PCB | |

| Fitur | kapabilitas |

| Count Layer | 4-60L |

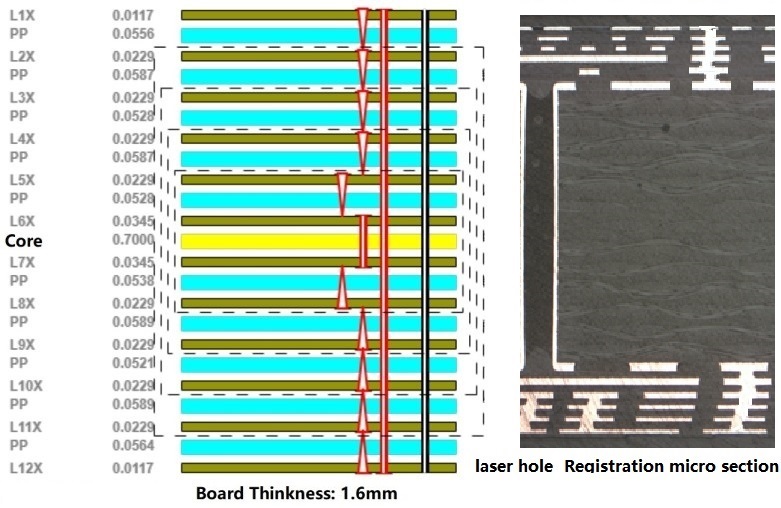

| Kasedhiya Teknologi PCB HDI | 1 + N + 1 |

| 2 + N + 2 | |

| 3 + N + 3 | |

| 4 + N + 4 | |

| 5 + N + 5 | |

| Lapisan apa wae | |

| Kandel | 0.3mm-6mm |

| Jembar lan Spasi baris minimal | 0.05mm / 0.05mm (2mil / 2mil) |

| BGA PITCH | 0,35mm |

| Ukuran Bor Min laser | 0.075mm (3nil) |

| Ukuran Bor Min mekanis | 0.15mm (6mil) |

| Aspek Rasio kanggo bolongan laser | 0,9: 1 |

| Rasio Aspek liwat bolongan | 16: 1 |

| Lumahing Rampung | HASL, HASL, timah gratis, ENG, Timah, OSP, Silver Immersion, Driji Emas, Gold Hard Electroplating, OSP Selektif, ENEPIG.etc. |

| Liwat Isi Isi | Via dilapisi lan diisi epoxy konduktif utawa non-konduktif banjur ditutup lan dilapis |

| Isi tembaga, perak isi | |

| Laser liwat tembaga dilapisi mati | |

| Registrasi | ± 4mil |

| Topeng Solder | Ijo, Abang, Kuning, Biru, Putih, Ireng, Ungu, Matte Ireng, Matte ijo. |

Sinau luwih lengkap babagan produk YMS

Waca warta liyane

Proses Produksi PCB HDI

Tulis pesen kene lan ngirim kanggo kita