Flex rigid Board semi flex PCB Black Soldermask| YMSPCB

What is Semi-Flex PCB?

Proses manufaktur tradisional PCB semi-fleksibel nggunakake bahan FR-4 sing mlengkung lan nggawe PCB miturut proses manufaktur PCB tradisional sing kaku, banjur nggunakake teknologi panggilingan jero kanggo nyuda wilayah sing kudu ditekuk tingkat keluwesan tartamtu, supaya bisa memenuhi syarat sambungan mlengkung Déwan.

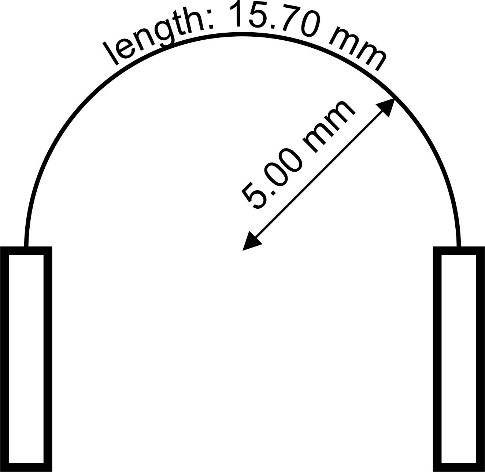

Kalkulator dawa SEMI-FLEX: (2 x Π x radius bend) x (sudhut tikungan / 360 °)

Contone, mlengkung kaping 5 kanthi sudut 180 derajat kanthi radius 5mm mbutuhake dawa minimal bagean semi-fleks 15,7mm

YMS Semi-Flex PCB manufaktur :

| Tinjauan kapabilitas pabrikan YMS Semi-Flex PCB | ||

| Fitur | kapabilitas | |

| Count Layer | 2-20L, kanthi 1 - 2 lapisan konduktif ing bagean fleksibel | |

| Kandel Fleksibel kaku | 0,5mm-5.0mm | |

| Kekandelan PCB ing bagean lentur | 0,15-0.8mm ± 0,05mm | |

| tembaga Kandel | 1 / 4OZ-10OZ | |

| Jembar lan Spasi baris minimal | 0.05mm / 0.05mm (2mil / 2mil) | |

| Stiffeners | Baja tahan karat , PI , FR4 , Aluminium lsp. | |

| Materi | FR4, tembaga RA, tembaga HTE, adesif, Bondply , coverlayer, soldermask fleksibel | |

| Ukuran Bor Min mekanis | 0.15mm (6mil) | |

| Ukuran bolongan laser min: | 0,075mm (3mil) | |

| Lumahing Rampung | Rampung permukaan mikro Microt / RF PCB sing cocog: Nikel Elektrol, Emas Immersion, ENEPIG, HASL gratis timbal, Silver Immersion. Lsp. | |

| Topeng Solder | Ijo, Abang, Kuning, Biru, Putih, Ireng, Ungu, Matte Ireng, Matte ijo. | |

| Covrelay (Bagian Flex) | Coverlay Kuning, Tutup Putih, Tutup Ireng |

|

Sinau luwih lengkap babagan produk YMS

Waca warta liyane

What is a rigid flex board?

The rigid-flex board is a flexible circuit board(FPC) and a rigid circuit board (PCB), which are combined together according to the relevant process requirements through pressing and other processes in the PCB proofing to form a circuit board with FPC characteristics and PCB characteristics.

What is difference between rigid and flexible boards?

As the names suggest, a rigid PCB is a circuit board built on a rigid base layer that cannot bend, while a flexible PCB, also called a flex circuit, is built on a flexible base capable of bending, twisting and folding.

Where are rigid flex PCBs used?

You’ll find them in commercial, industrial and military applications. From digital cameras to cell phones to smart devices, they serve them all. Especially in the medical industry for developing pacemakers for their weight reduction, space, and flexible capabilities.