High Tg PCB Advanced PCB Manufacturing| YMS PCB

How do I classify high-TG materials?

| Materi | TG | MOT |

| FR4-standard-TG | 130°C | 110°C |

| FR4-mittel-TG | 150°C | 130°C |

| FR4-hoch-TG | 170°C | 150°C |

| Polyimid-Super-hoch-TG-Material | 250°C | 230°C |

ome common high-frequency materials do not mention TGs in their datasheets. This is due to the original meaning of TG: "temperature of glass transition". Many ceramics- or PTFE-based materials do simply not contain any glass fibres and therefore have no technical TG. Generally, this fact also applies to Polyimides (PI). However, you can usually assume a TG of at least 200°C for Polyimide, ceramics or PTFE-materials. In this case the TG simply stands for temperature resistance.

You may apply the following values:

| Material type | Typical „TG“ |

| CEM1 | 110-130°C |

| FR4 | 120-180°C |

| PTFE | 200-260°C |

| Ceramic | 200-300°C |

| Polyimide | 200-350°C |

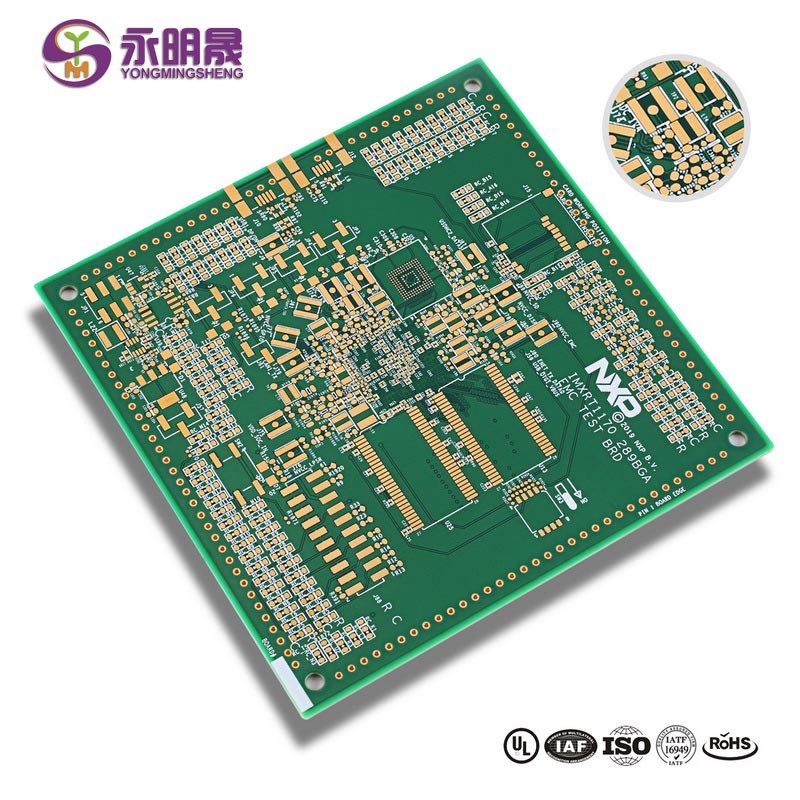

YMS High Tg PCB manufacturing capabilities:

|

YMS High Tg PCB manufacturing capabilities overview |

||

| Fitur | kapabilitas | |

| Count Layer | 3-60L | |

| Kasedhiya Teknologi PCB Multilayer | Liwat bolongan kanthi Aspek Rasio 16: 1 | |

| dikubur lan wuta liwat | ||

| Hibrida | High Frequency Material such as RO4350B and FR4 TG 180°Mix etc. | |

| High Speed Material such as M7NE and FR4 TG 180°Mix etc. | ||

| Kandel | 0.3mm-8mm | |

| Jembar lan Spasi baris minimal | 0.05mm / 0.05mm (2mil / 2mil) | |

| BGA PITCH | 0,35mm | |

| Ukuran Bor Min mekanis | 0.15mm (6mil) | |

| Rasio Aspek liwat bolongan | 16: 1 | |

| Lumahing Rampung | HASL, HASL, timah gratis, ENG, Timah, OSP, Silver Immersion, Driji Emas, Gold Hard Electroplating, OSP Selektif, ENEPIG.etc. | |

| Liwat Isi Isi | Via dilapisi lan diisi epoxy konduktif utawa non-konduktif banjur ditutup lan dilapisi (VIPPO) | |

| Isi tembaga, perak isi | ||

| Registrasi | ± 4mil | |

| Topeng Solder | Ijo, Abang, Kuning, Biru, Putih, Ireng, Ungu, Matte Ireng, Matte ijo. | |

Sinau luwih lengkap babagan produk YMS

Waca warta liyane

Tulis pesen kene lan ngirim kanggo kita