Ọ bụrụ na PCB nwere ala ọzọ, e nwere SGND, AGND, GND, wdg, dabere na ọnọdụ nke PCB elu , a na-eji isi "ala" mee ihe dị ka ihe ntụaka maka mkpuchi ọla kọpa nke onwe ya, ya bụ, a na-ejikọta ala ọnụ. .

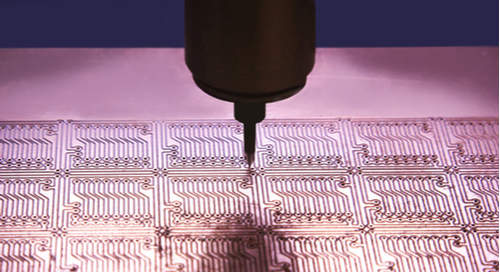

Ụdị ihe mkpuchi ọla kọpa

Ejuputara ihe owuwu site na-in-pad chọrọ site n'oghere ka echie ọla kọpa ka ọ na-agafe akara n'etiti n'ígwé na PCB multilayer. Ihe mkpuchi a na-ejikọ na paịlị ndị ọzọ na sistemu-in-pad, yana ozugbo na nchọta na-eji obere mgbanaka anular. Ihe owuwu ndị a dị mkpa, mana amaara ha na ha nwere ụfọdụ nsogbu ntụkwasị obi n'okpuru ịgba ígwè ọkụ ugboro ugboro.

Ụkpụrụ IPC 6012E gbakwunyere na nso nso a ihe mkpuchi ọla kọpa chọrọ n'ụdị-in-pad. Ihe mkpuchi ọla kọpa juru eju kwesịrị ịga n'ihu n'akụkụ ọnụ nke oghere ahụ wee gbatịa na mgbanaka anular gbara ya gburugburu site na pad. Ihe a chọrọ na-eme ka ntụkwasị obi dịkwuo mma site na ịkwanye ma nwee ike belata ọdịda n'ihi mgbawa, ma ọ bụ n'ihi nkewa n'etiti atụmatụ elu na plated site na oghere.

Ihe mkpuchi ọla kọpa jupụtara na-apụta n'ụdị abụọ. Mbụ, a na-aga n'ihu ọla kọpa film nwere ike tinye n'ime n'ime a via, nke mgbe ahụ, ọbọp n'elu na ala n'ígwé na nsọtụ nke via. Nke a ọla kọpa Kechie plating ahụ na-etolite na via mpe mpe akwa na Chọpụta na-eduga na via, eke a na-aga n'ihu ọla kọpa Ọdịdị.

N'aka nke ọzọ, via nwere ike inwe pad nke ya dị iche iche kpụrụ na nsọtụ via ahụ. Nke a dị iche iche mpe mpe akwa na-ejikọta na akara ma ọ bụ ụgbọ elu ala. Ihe mkpuchi ọla kọpa nke na-ejupụta via wee kechie n'elu mpempe akwụkwọ a dị n'èzí, na-akpụ njikọ n'etiti ihe mkpuchi ọla kọpa na site na pad. Ụfọdụ njikọ na-eme n'etiti ndochi njuputa na site na pad, ma ha abụọ anaghị ejikọta ọnụ ma ghara ịmepụta otu usoro na-aga n'ihu.

Enwere ọtụtụ ihe kpatara ịkwanye ọla kọpa:

1. EMC. Maka nnukwu mpaghara ala ma ọ bụ ọla kọpa, ọ ga-echebe, yana ụfọdụ pụrụ iche, dị ka PGND iji chebe ya.

2. PCB usoro chọrọ. N'ozuzu, iji hụ na plating mmetụta, ma ọ bụ laminate na-adịghị deformed, ọla kọpa tọrọ maka PCB oyi akwa na obere wiring.

3. Ihe nrịbama nke iguzosi ike n'ezi ihe, nye akara ngosi dijitalụ dị elu nke ukwuu ụzọ nloghachi zuru oke, ma belata wiring nke netwọk DC. N'ezie, enwere ikpo ọkụ ọkụ, ntinye ngwaọrụ pụrụ iche chọrọ ịkwanye ọla kọpa na ihe ndị ọzọ.

Otu uru dị ukwuu nke ịkwanye ọla kọpa bụ iji belata nkwụsị nke ala ala (ihe a na-akpọ mgbochi nnyonye anya na-ebutekwa nnukwu akụkụ nke nkwụsị nkwụsị nke ala). Enwere otutu mmiri iyi na sekit dijitalụ, n'ihi ya, ọ dị mkpa ka ọ belata nkwụsị nke ala. A na-ekwenyekarị na sekit ndị mejupụtara kpamkpam nke ngwaọrụ dijitalụ kwesịrị ịgbado n'akụkụ buru ibu, yana maka sekit analọg, mgbanaka ala nke emere site na platin ọla kọpa nwere ike ime ka nnyonye anya njikọ electromagnetic dị ala (ma ewezuga sekit ugboro ugboro). Ya mere, ọ bụghị sekit ga-abụ ọla kọpa (BTW: ọla kọpa mesh dị mma karịa ngọngọ dum).

Ihe ọ pụtara ịgbanye ọla kọpa sekit:

1. ọla kọpa na waya ala jikọtara, nke a nwere ike ibelata mpaghara akaghị

2. nnukwu ebe a na-etinye ọla kọpa dị ka ibelata nguzogide nke waya ala, na-ebelata nrụgide nrụgide site na isi ihe abụọ a A na-ekwu na ma ala dijitalụ na ala analog kwesịrị ịbụ ọla kọpa iji mee ka ikike mgbochi nnyonye anya dịkwuo elu, na na. frequencies dị elu, ala dijitalụ na ala analọg kwesịrị ikewapụ iji dina ọla kọpa, wee jikọta ya site na otu ebe, otu ebe nwere ike iji waya mee mgbanwe ole na ole na mgbanaka magnetik wee jikọọ. Otú ọ dị, ọ bụrụ na ugboro ugboro adịghị elu, ma ọ bụ ọnọdụ ọrụ nke ngwá ọrụ adịghị njọ, ị nwere ike izuike dịtụ. Enwere ike ịgụta kristal dị ka isi iyi dị elu na sekit. Ị nwere ike idowe ọla kọpa gburugburu ma gbanye ihe mkpuchi kristal, nke ka mma.

Ọ bụrụ na ị nwere mmasị ịmụtakwu banyere YMS PCB, kpọtụrụ anyị n'oge ọ bụla.

Mụtakwuo maka ngwaahịa YMS

Ndị mmadụ na-ajụkwa

Oge nzipu: Eprel-08-2022