Flex rigid Board semi flex PCB Black Soldermask| YMSPCB

What is Semi-Flex PCB?

Proses pembuatan PCB semi-fleksibel yang paling tradisional adalah mengadopsi bahan FR-4 pembengkokan dan membuat PCB sesuai dengan proses pembuatan PCB kaku tradisional, dan kemudian menggunakan teknologi penggilingan dalam untuk menipiskan area yang perlu ditekuk sehingga memiliki tingkat fleksibilitas tertentu, untuk memenuhi persyaratan sambungan lentur perakitan.

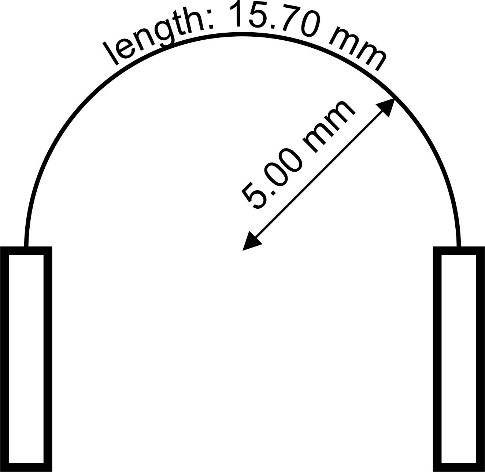

Kalkulator panjang SEMI-FLEX: (2 x Π x radius tikungan) x (sudut tikungan / 360 °)

Misalnya, menekuk 5 kali pada sudut 180 derajat dengan jari-jari 5mm membutuhkan panjang minimum bagian semi-lentur 15,7mm.

Kemampuan PCB Semi-Flex pabrikan capa :

| Ikhtisar kapabilitas manufaktur YMS Semi-Flex PCB | ||

| Fitur | kemampuan | |

| Jumlah Lapisan | 2-20L, dengan 1 - 2 lapisan konduktif di bagian yang fleksibel | |

| Ketebalan Kaku-Lentur | 0,5 mm-5,0 mm | |

| Ketebalan PCB di bagian flex | 0,15-0,8 mm ± 0,05 mm | |

| Ketebalan tembaga | 1 / 4OZ-10OZ | |

| Lebar dan Spasi Garis Minimum | 0.05mm / 0.05mm (2mil / 2mil) | |

| Pengaku | Baja tahan karat, PI, FR4, Aluminium dll. | |

| Bahan | FR4, RA tembaga, HTE tembaga, perekat, Bondply, lapisan penutup, masker solder fleksibel | |

| Ukuran Bor mekanik Min | 0,15 mm (6mil) | |

| Ukuran Lubang laser Min: | 0,075mm (3mil) | |

| Permukaan Selesai | Selesai permukaan gelombang mikro / RF PCB yang sesuai: Electroless Nickel, Immersion Gold, ENEPIG, Lead free HASL, Immersion Silver.etc. | |

| Topeng solder | Hijau, Merah, Kuning, Biru, Putih, Hitam, Ungu, Matte Black, Matte green. Dll. | |

| Covrelay (Bagian Fleksibel) | Coverlay Kuning, Coverlay Putih, Coverlay Hitam |

|

Pelajari lebih lanjut tentang produk YMS

Baca lebih banyak berita

What is a rigid flex board?

The rigid-flex board is a flexible circuit board(FPC) and a rigid circuit board (PCB), which are combined together according to the relevant process requirements through pressing and other processes in the PCB proofing to form a circuit board with FPC characteristics and PCB characteristics.

What is difference between rigid and flexible boards?

As the names suggest, a rigid PCB is a circuit board built on a rigid base layer that cannot bend, while a flexible PCB, also called a flex circuit, is built on a flexible base capable of bending, twisting and folding.

Where are rigid flex PCBs used?

You’ll find them in commercial, industrial and military applications. From digital cameras to cell phones to smart devices, they serve them all. Especially in the medical industry for developing pacemakers for their weight reduction, space, and flexible capabilities.