HDI PCB 12 Layer 2 Step HDI Board | YMS PCB

parameter

Lapisan: 12

Base Material:FR4 High Tg EM827

Ketebalan: 1.2 ± 0.1mm

Min.Hole Size:0.15mm

Minimum Line Width/Space:0.075mm/0.075mm

Jarak Bebas Minimum antara PTH Lapisan Dalam dan Garis : 0.2mm

Size:101mm×55mm

Aspect Ratio: 8: 1

Permukaan pengobatan: ENIG

Speciality: Laser via copper plated shut,VIPPO Technology,Blind Via and Buried Hole

Aplikasi: Telekomunikasi

What is HDI PCBs?

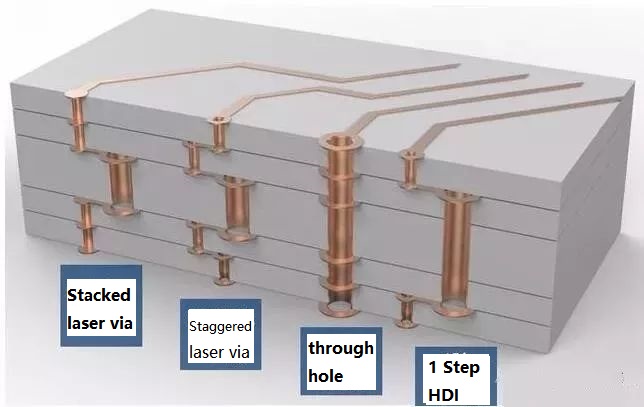

High density interconnect (HDI) PCBs represent one of the fastest-growing segments of the printed circuit board market. Because of its higher circuitry density, the HDI PCB design can incorporate finer lines and spaces, smaller vias and capture pads, and higher connection pad densities. A high-density PCB features blind and buried vias and often contains microvias that are .006 in diameter or even less.

1.Multi-langkah HDI memungkinkan hubungan antara setiap lapisan;

2.Cross-layer pengolahan laser dapat meningkatkan tingkat kualitas multi-langkah HDI;

Kombinasi 3. HDI dan bahan frekuensi tinggi, laminasi berbasis logam, FPC dan laminasi khusus lainnya dan proses memungkinkan kebutuhan kepadatan tinggi dan frekuensi tinggi, budidaya panas tinggi, atau perakitan 3D.

Kemampuan manufaktur YMS HDI PCB :

| Ikhtisar kapabilitas manufaktur YMS HDI PCB | |

| Fitur | kemampuan |

| Jumlah Lapisan | 4-60L |

| Tersedia Teknologi HDI PCB | 1 + N + 1 |

| 2 + N + 2 | |

| 3 + N + 3 | |

| 4 + N + 4 | |

| 5 + N + 5 | |

| Lapisan apa saja | |

| Ketebalan | 0,3 mm-6 mm |

| Lebar dan Spasi Garis Minimum | 0.05mm / 0.05mm (2mil / 2mil) |

| BGA PITCH | 0,35 mm |

| Ukuran Bor Laser Min | 0,075mm (3nil) |

| Ukuran Bor mekanik Min | 0,15 mm (6mil) |

| Rasio Aspek untuk lubang laser | 0,9: 1 |

| Rasio Aspek untuk lubang tembus | 16: 1 |

| Permukaan Selesai | HASL, HASL bebas timah, ENIG, Timah Perendaman, OSP, Perak Perendaman, Jari Emas, Emas Keras Elektroplating, OSP Selektif, ENEPIG.etc. |

| Melalui Opsi Isi | Jalur via dilapisi dan diisi dengan epoksi konduktif atau non-konduktif kemudian ditutup dan dilapisi |

| Isi tembaga, isi perak | |

| Laser melalui tutup berlapis tembaga | |

| Registrasi | ± 4mil |

| Topeng solder | Hijau, Merah, Kuning, Biru, Putih, Hitam, Ungu, Matte Black, Matte green. Dll. |

Kamu mungkin suka:

1、The application range and circuit advantage of HDI board are introduced

2、PCB production skills: HDI board CAM production method

3 PCB design of 1 step, 2 step and 3step HDI

6. Bagaimana PCB keramik dibuat?

Pelajari lebih lanjut tentang produk YMS

What is HDI in PCB?

HDI Boards – High Density Interconnect

What are the layers of a PCB?

Substrate Layer.

Copper Layer.

Soldermask layer.

Silkscreen layer.

What is HDI stackup?

HDI is short for high density interconnect, and refers to the use of buried, blind and micro vias as well as any layer HDIs to create compact boards.