Hot Sale for China HDI High Density Printed Circuit Board From PCBA Manufacturer

That has a sound business credit history, outstanding after-sales service and modern producing facilities, we have earned an superb popularity amid our buyers across the planet for Hot Sale for China HDI High Density Printed Circuit Board From PCBA Manufacturer, Honesty is our principle, experienced procedure is our do the job, provider is our goal, and customers’ gratification is our future!

That has a sound business credit history, outstanding after-sales service and modern producing facilities, we have earned an superb popularity amid our buyers across the planet for China PCBA, Pcb, We have now won a good reputation among overseas and domestic clients. Adhering to the management tenet of “credit oriented, customer first, high efficiency and mature services”, we warmly welcome friends from all walks of life to cooperate with us.

The basic meaning of high Tg PCB

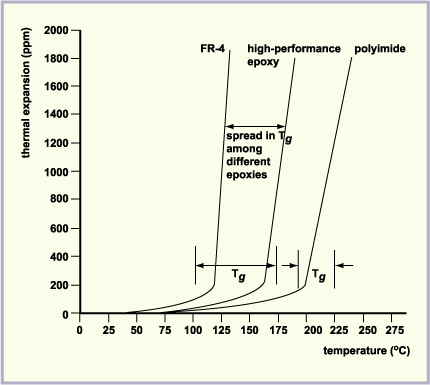

When the temperature of high Tg printed circuit board rises to a certain threshold, the substrate will change from “glass state” to “rubber state”, and the temperature at this time is called the glass transition temperature (Tg) of the board.In other words, Tg is the highest temperature (℃) at which the substrate remains rigid.That is to say, the common PCB substrate material in the high temperature, continuous softening, deformation, melting and other phenomena, but also in the performance of the mechanical and electrical characteristics of the sharp decline, which affects the service life of the product (I think we do not want to see their own products appear in this case).

The main characteristics of high Tg PCB

Generally, Tg plates are above 130℃, high Tg is generally greater than 170℃, and medium Tg is about greater than 150℃.

PCB printed boards with Tg≥170℃ are usually referred to as high Tg printed boards.

With the improvement of Tg of substrate, the heat resistance, moisture resistance, chemical resistance and stability of PCB will be improved.The higher the TG value, the better the temperature resistance of the plate, especially in lead-free process, high TG is more widely used.

Therefore, the difference between general fr-4 and high Tg is as follows: under high temperature, especially under heat after hygroscopicity, the mechanical strength, dimensional stability, adhesion, water absorption, thermal decomposition, thermal expansion and other conditions of the materials are different, and high Tg products are obviously better than ordinary PCB substrate materials.

YMS High Tg PCB manufacturing capabilities:

|

YMS High Tg PCB manufacturing capabilities overview |

||

| Feature | capabilities | |

| Layer Count | 3-60L | |

| Available Multilayer PCB Technology | Through hole with Aspect Ratio 16:1 | |

| buried and blind via | ||

| Hybrid | High Frequency Material such as RO4350B and FR4 TG 180°Mix etc. | |

| High Speed Material such as M7NE and FR4 TG 180°Mix etc. | ||

| Thickness | 0.3mm-8mm | |

| Minimum line Width and Space | 0.05mm/0.05mm(2mil/2mil) | |

| BGA PITCH | 0.35mm | |

| Min mechanical Drilled Size | 0.15mm(6mil) | |

| Aspect Ratio for through hole | 16:1 | |

| Surface Finish | HASL, Lead free HASL,ENIG,Immersion Tin, OSP, Immersion Silver, Gold Finger, Electroplating Hard Gold, Selective OSP,ENEPIG.etc. | |

| Via Fill Option | The via is plated and filled with either conductive or non-conductive epoxy then capped and plated over(VIPPO) | |

| Copper filled, silver filled | ||

| Registration | ±4mil | |

| Solder Mask | Green, Red, Yellow, Blue, White, Black, Purple, Matte Black, Matte green.etc. | |

You May Like:

1、How to make high frequency PCB

2、Common knowledge of high frequency PCB wiring (1)

3、Common knowledge of high frequency PCB wiring (2)

Board2-300x300.jpg)