Aluminium PCB Manufacturing Txheej txheem

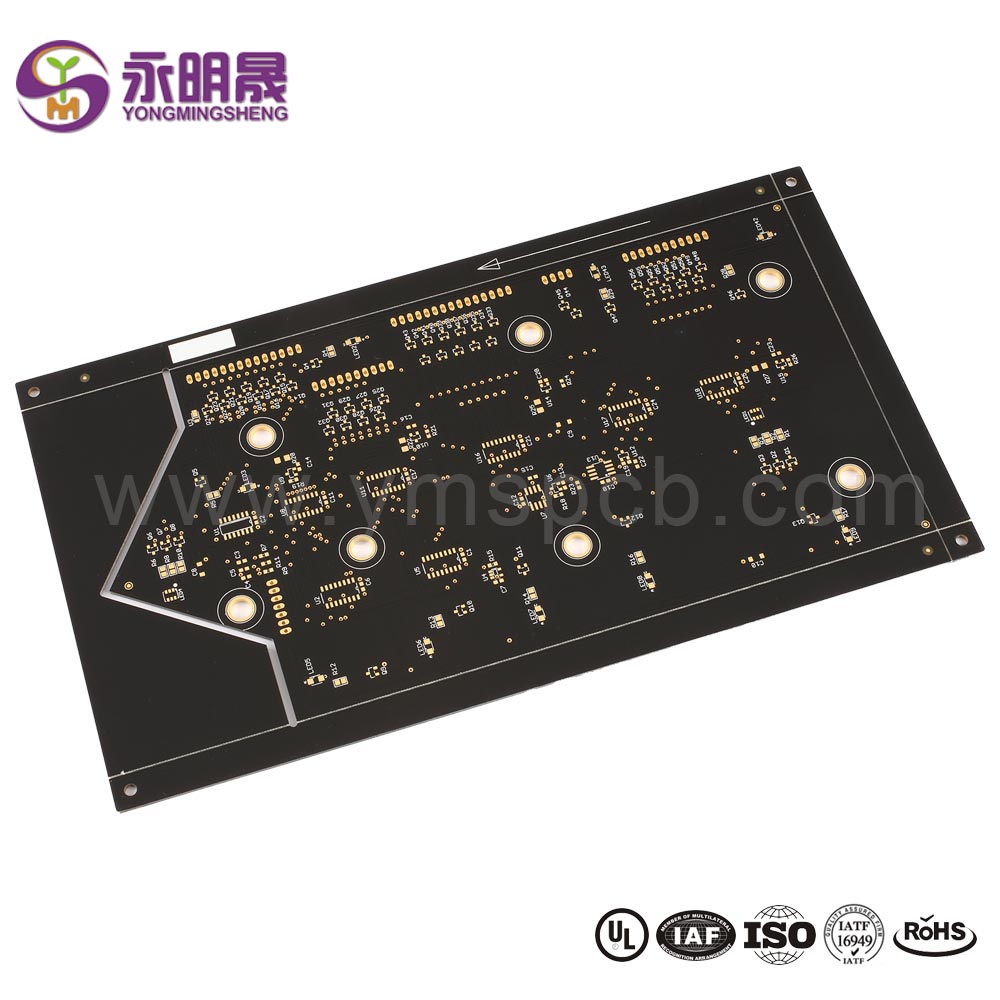

Aluminium PCB Manufacturing ProcessThe manufacturing txheej txheem ntawm txhuas PCB nrog OSP nto tiav: Txiav → Drilling → Circuit Court → Acid/alkaline etching → Solder Mask → Silkscreen → V-cut → PCB Test → OSP → FQC → FQA → Packing → Delivery.

Kev tsim cov txheej txheem ntawm txhuas PCB nrog HASL nto tiav: Txiav → Drilling → Circuit Court → Acid / alkaline etching → Solder Mask → Silkscreen → HASL → V-cut → PCB Test → FQC → FQA → Packing → Delivery.

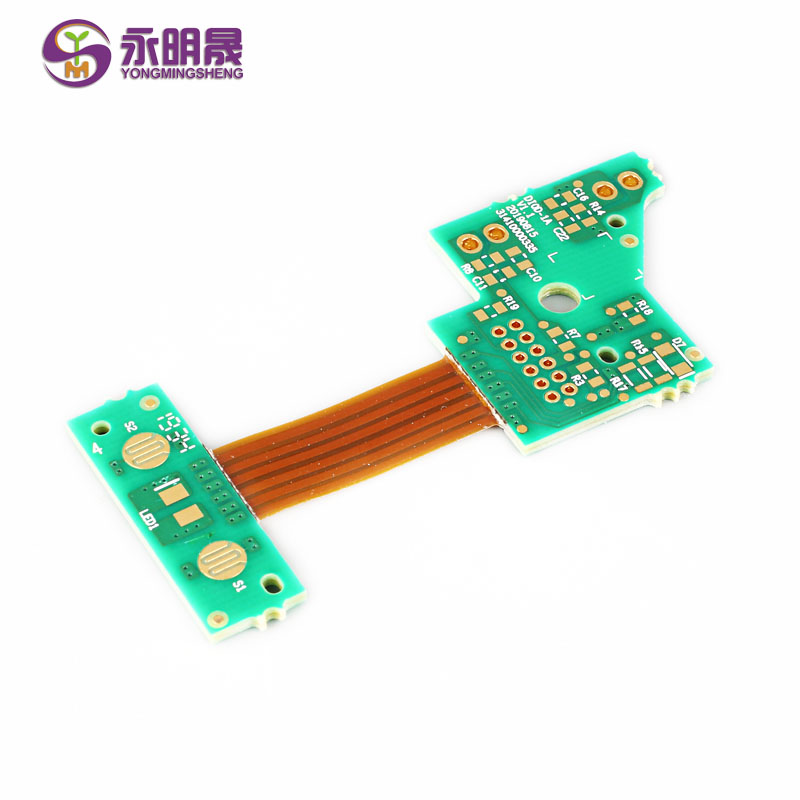

YMSPCB tuaj yeem muab cov tub ntxhais aluminium PCB nrog tib qhov chaw ua tiav raws li FR-4 PCB: Immersion Kub / nyias / nyiaj, OSP, thiab lwm yam.

Nyob rau hauv tus txheej txheem ntawm kev tsim ib qho txhuas PCB, ib txheej nyias ntawm dielectric yog ntxiv ntawm txheej Circuit Court thiab lub hauv paus txheej. Cov txheej ntawm dielectric no yog ob qho tib si hluav taws xob insulating, nrog rau thermally conductive. Tom qab ntxiv cov txheej txheem dielectric, txheej txheej hauv Circuit Court lossis cov ntawv ci tooj liab yog etched

Daim ntawv ceeb toom

1. Muab cov laug cam tso rau hauv lub tawb-txuas lossis cais lawv nrog cov ntawv lossis cov ntawv yas kom tsis txhob khawb thaum lub sijhawm thauj khoom tag nrho.

2. Siv rab riam los khawb ib txheej insulated nyob rau hauv txhua txoj kev yog tsis tso cai thaum lub sij hawm tag nrho cov khoom.

3. Rau cov laug cam, cov khoom siv hauv paus tsis tuaj yeem drilled tab sis tsuas yog cim "X" los ntawm roj-xov.

4. Tag nrho cov qauv tshuaj xyuas yog ib qho yuav tsum tau vim tias tsis muaj txoj hauv kev los daws qhov teeb meem ntawm cov qauv tom qab etching.

5. Ua 100% IQC kev kuaj xyuas rau tag nrho cov khoom lag luam tawm raws li peb lub tuam txhab cov qauv.

6. Sib sau ua ke tag nrho cov khoom tsis zoo ua ke (xws li cov xim dim & khawb ntawm AI nto) kom rov ua dua.

7. Txhua qhov teeb meem thaum lub sijhawm tsim khoom yuav tsum tau qhia rau cov neeg ua haujlwm muaj feem xyuam rau lub sijhawm kom daws tau.

8. Tag nrho cov txheej txheem yuav tsum tau ua nruj me ntsis raws li qhov yuav tsum tau ua.

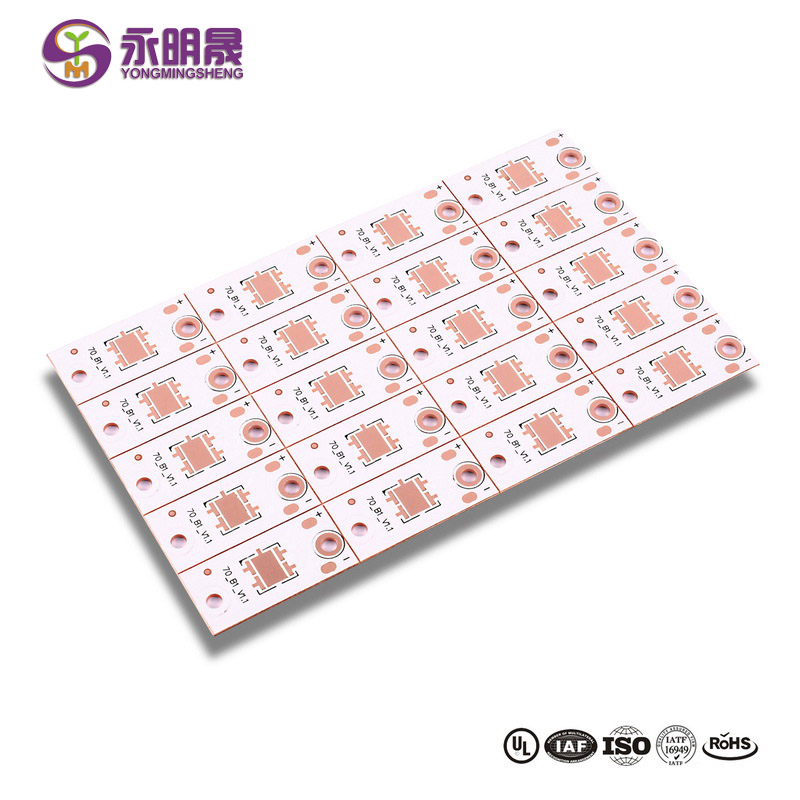

Aluminium luam ntawv Circuit Court boards tseem hu ua hlau puag PCBs thiab muaj cov hlau-raws li laminates them los ntawm tooj liab ntawv ci txheej txheej. Lawv yog ua los ntawm cov hlau phaj uas yog kev sib xyaw ntawm txhuas, magnesium thiab silumin (Al-Mg-Si). Aluminium PCBs xa cov hluav taws xob zoo heev, muaj peev xwm thermal zoo thiab kev ua haujlwm siab, thiab lawv txawv ntawm lwm cov PCBs hauv ntau txoj hauv kev tseem ceeb.

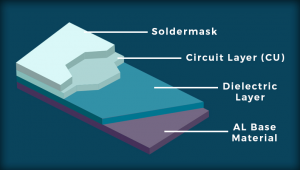

Aluminium PCB Txheej

LUB BASE LAYER

Cov txheej no muaj cov aluminium alloy substrate. Kev siv cov txhuas ua rau hom PCB no yog qhov kev xaiv zoo tshaj plaws rau kev siv tshuab los ntawm lub qhov, sib tham tom qab.

THERMAL Rwb thaiv tsev txheej

Cov txheej no yog ib qho tseem ceeb ntawm cov PCB. Nws muaj cov khoom siv ceramic uas muaj cov khoom zoo viscoelastic, zoo thermal kuj thiab tiv thaiv PCB tiv thaiv txhua yam thiab thermal stresses.

LUB CIRCUIT LAYER

Cov txheej hauv Circuit Court muaj cov ntawv ci tooj liab uas tau hais dhau los. Feem ntau, PCB cov tuam txhab siv tooj liab foils xws li ib mus rau 10 ooj.

LUB DIELECTRIC LAYER

Lub dielectric txheej ntawm rwb thaiv tsev absorbs tshav kub raws li tam sim no ntws los ntawm circuits. Qhov no yog pauv mus rau aluminium txheej, qhov twg cov cua sov yog dispersed.

Kev ua tiav lub teeb pom kev zoo tshaj plaws tau ua rau muaj cua sov ntxiv. PCBs nrog kev txhim kho thermal kuj txuas ntxiv lub neej ntawm koj cov khoom tiav. Ib lub chaw tsim khoom tsim nyog yuav muab kev tiv thaiv zoo tshaj rau koj, txo cov cua sov thiab ib feem kev ntseeg tau. Ntawm YMS PCB, peb tuav peb tus kheej mus rau cov txheej txheem tshwj xeeb thiab ua haujlwm zoo uas koj xav tau.

Kawm paub ntau ntxiv txog YMS cov khoom

Post lub sij hawm: Jan-20-2022