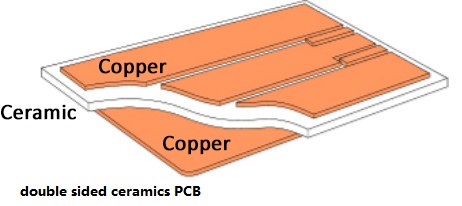

Ceramic PCB ib leeg thiab ob sab ceramics PCB tsim Ceramic Substrates | YMS PCB

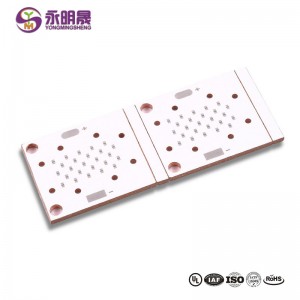

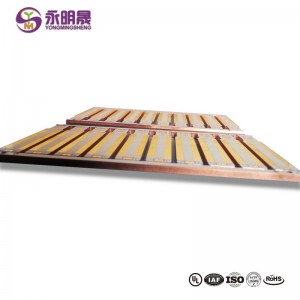

Ceramic PCB: ceramic substrate circuit board

Ceramic Substrate piav qhia txog cov txheej txheem tshwj xeeb uas cov tooj liab aluminium ntawv ci tau ncaj qha mus rau thaj chaw saum npoo (ib sab lossis ob sab) ntawm alumina (Al2O3) lossis hnav aluminium nitride (AlN) ceramic substrate thaum tshav kub kub. Piv nrog rau tus qauv FR-4 los yog lub teeb yuag aluminium substrate, lub ultra-thin composite substrate ua tau tshwj xeeb hluav taws xob rwb thaiv tsev efficiency, siab thermal conductivity, tshwj xeeb mos solderability thiab kuj muaj siab daim ntawv cog lus, thiab kuj yuav engraved ntau cov duab zoo li PCB, nrog zoo heev uas twb muaj lawm lugging peev xwm. Nws tsim nyog rau cov khoom uas muaj lub cim sov siab (high-brightness LED, hnub ci zog), nrog rau nws cov huab cua zoo heev tiv thaiv yog qhov zoo dua rau qhov chaw ntxhib sab nraud. Ceramic Circuit Board Technology Taw Qhia

Vim li cas thiaj siv cov khoom siv ceramics los tsim cov boards? Ceramic circuit boards yog ua los ntawm cov hluav taws xob ceramics thiab tuaj yeem ua rau ntau yam duab. Cov yam ntxwv ntawm qhov kub thiab txias tsis kam thiab cov hluav taws xob hluav taws xob siab ntawm cov khoom siv hluav taws xob ceramic yog qhov tseem ceeb tshaj plaws. Qhov zoo ntawm dielectric tsis tu ncua thiab dielectric poob, siab thermal conductivity, zoo tshuaj stability, thiab zoo xws li thermal expansion coefficient rau cov khoom tseem ceeb. Kev tsim cov khoom siv hluav taws xob ceramic yuav siv LAM thev naus laus zis, uas yog laser nrawm ua kom metallization tshuab. Lawv yog siv nyob rau hauv LED teb, high-power fais semiconductor modules, semiconductor tub yees, hluav taws xob cua sov, hluav taws xob tswj circuits, fais fab hybrid circuits, ntse hwj chim Cheebtsam, high-frequency switching fais fab mov, solid-state relays, automotive electronics, kev sib txuas lus, aerospace, thiab tub rog electronics Cheebtsam.

Qhov zoo ntawm Ceramic PCB

Tsis zoo li cov tsoos FR-4, cov khoom siv ceramic muaj qhov ua tau zoo thiab kev ua haujlwm ntawm hluav taws xob, muaj cov thermal conductivity, tshuaj stability, thermal stability zoo, thiab lwm yam khoom uas organic substrates tsis muaj. Nws yog cov khoom ntim tshiab zoo tshaj plaws rau kev tsim cov khoom siv hluav taws xob loj thiab cov hluav taws xob hluav taws xob.

Lub ntsiab zoo:

siab dua thermal conductivity.

Ntau qhov sib piv thermal expansion coefficient.

Muaj zog thiab qis tsis kam hlau zaj duab xis alumina ceramic circuit board.

Lub solderability ntawm lub substrate yog zoo, thiab siv kub yog siab.

Zoo rwb thaiv tsev.

Tsawg-tsawg zaus poob.

High-density sib dhos ua tau.

Nws tsis muaj cov khoom xyaw organic, tiv taus cosmic rays, muaj kev ntseeg siab hauv aerospace, thiab muaj lub neej ua haujlwm ntev.

Cov txheej tooj liab tsis muaj oxide txheej thiab tuaj yeem siv tau ntev hauv qhov chaw txo qis. Ceramic PCBs tuaj yeem muaj txiaj ntsig zoo thiab muaj txiaj ntsig zoo rau cov ntawv luam tawm Circuit Court boards hauv cov lag luam no thiab ntau lwm yam lag luam, nyob ntawm seb koj xav tau kev tsim thiab tsim khoom.

Ceramic PCB yog ib hom cua sov ua cov hmoov ceramic thiab cov organic binder, thiab cov cua sov ua haujlwm organic ceramic PCB yog npaj ntawm thermal conductivity ntawm 9-20W / m. Nyob rau hauv lwm yam lus, ceramic PCB yog ib tug luam Circuit Court board nrog ceramic puag cov ntaub ntawv, uas yog heev thermally conductive cov ntaub ntawv xws li alumina, aluminium nitride, raws li zoo raws li beryllium oxide, uas yuav ua rau ib tug ceev cov nyhuv ntawm hloov tshav kub kom deb ntawm kub thiab dissipating. nws hla tag nrho saum npoo. Dab tsi ntxiv, ceramic PCB yog tsim nrog LAM thev naus laus zis, uas yog laser nrawm ua kom metallization tshuab. Yog li ceramic PCB yog qhov muaj ntau yam uas tuaj yeem siv qhov chaw ntawm tag nrho cov khoom siv hluav taws xob luam tawm nrog kev tsim kho tsawg dua nrog kev ua tau zoo.

Sib nrug los ntawm MCPCB , yog tias koj xav siv PCB hauv kev kub siab, kev rwb thaiv tsev siab, siab zaus, siab kub, thiab siab txhim khu kev qha thiab cov khoom siv hluav taws xob me me, ces Ceramic PCB yuav yog qhov zoo tshaj plaws rau koj xaiv.

Vim li cas Ceramic PCB thiaj li muaj kev ua tau zoo? Koj tuaj yeem pom luv luv ntawm nws cov qauv yooj yim thiab tom qab ntawd koj yuav nkag siab.

- 96% lossis 98% Alumina (Al2O3), Aluminium Nitride (ALN), lossis Beryllium Oxide (BeO)

- Cov khoom siv: Rau nyias, tuab zaj duab xis thev naus laus zis, nws yuav yog nyiaj palladium (AgPd), kub pllladium (AuPd); Rau DCB (Direct Copper Bonded) nws yuav yog tooj liab nkaus xwb

- Kev ntsuas kub: -55 ~ 850C

- Thermal conductivity nqi: 24W ~ 28W / mK (Al2O3); 150W ~ 240W / mK rau ALN, 220 ~ 250W / mK rau BeO;

- Max compression zog:> 7,000 N / cm2

- Kev tawg Voltage (KV / mm): 15/20/28 rau 0.25mm / 0.63mm / 1.0mm feem

- Thermal expansion conefficient (ppm / K): 7.4 (hauv qab 50 ~ 200C)

Hom ntawm ceramic PCBs

1. Kub kub ceramic PCB

2. Tsawg kub ceramic PCB

3.Thick zaj duab xis ceramic PCB

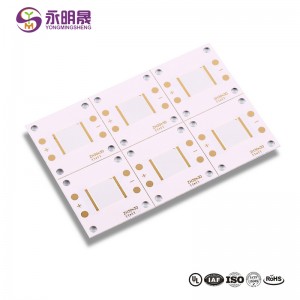

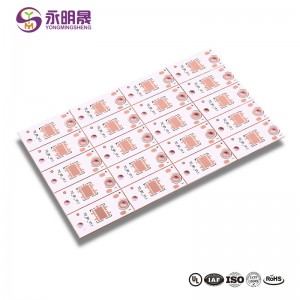

YMS Ceramic PCB tsim muaj peev xwm:

| YMS Ceramic PCB manufacturing peev xwm txheej txheem cej luam | ||

| Ntseg | muaj peev xwm | |

| Txheej Txheej | 1-2 L | |

| Khoom thiab Thickness | Al203: 0.15, 0.38, 0.5, 0.635, 1.0, 1.5, 2.0mm thiab lwm yam. | |

| SIN: 0.25, 0.38, 0.5, 1.0mm thiab lwm yam. | ||

| AIN: 0.15, 0.25, 0.38, 0.5, 1.0mm thiab lwm yam. | ||

| Thermal conductivity | Al203: Min. 24 W / mk txog 30W / mk | |

| SIB: Min. 85W / mk txog 100W / mk | ||

| AIN: Min. 150 W / mk txog 320 W / mk | ||

| Al2O3 | Al2O3 muaj lub teeb pom kev zoo dua - ua rau nws haum rau cov khoom siv LED. | |

| SIN | SiN muaj CTE qis heev. Ua ke nrog lub siab Repture Strength nws tuaj yeem tiv taus thermal shock. | |

| AlN | AlN muaj cov thermal conductivity zoo dua - ua rau nws tsim nyog rau kev siv hluav taws xob siab heev uas xav tau qhov zoo tshaj plaws thermal substrate. | |

| Pawg Ntsuas Thickness | 0.25mm-3.0 hli | |

| tooj liab Thickness | 0.5-10.5 hli | |

| Yam tsawg kawg kab Dav thiab qhov chaw | 0.075 hli / 0.075mm (3mil / 3mil) | |

| Tshwj Xeeb | Tej Txheeb Ze, Cov Neeg Tawm Tsam drilling.etc. | |

| Min mechanical Drilled Qhov Coob | 0.15 hli (6mil) | |

| Cov khoom siv conductors: | Rau nyias, tuab zaj duab xis tshuab, nws yuav yog nyiaj palladium (AgPd), kub pllladium (AuPd), Platinum Rau DCB (Direct Copper Bonded) nws yuav yog tooj liab nkaus xwb. | |

| Nto xaus | HASL, Lead dawb HASL, ENIG, Immersion Tin, OSP, Immersion Silver, Gold Finger, Electroplating Hard Kub, Xaiv OSP , ENEPIG.etc. | |

| Tus Neeg Muag Khoom Daim npog qhov ncauj | Ntsuab, Liab, Daj, Xiav, Dawb, Dub, Ntshav, Matte Dub, Matte green.etc. | |

| polished | Ra <0.1 um | |

| lapped | Ra <0.4um | |

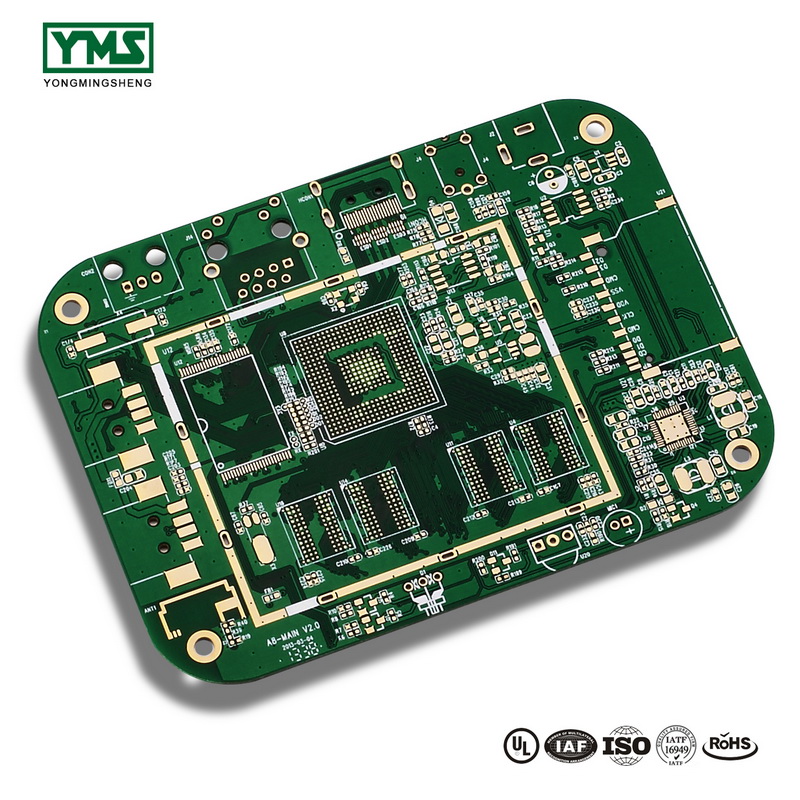

Kawm paub ntau ntxiv txog YMS cov khoom

Nyeem xov xwm ntxiv