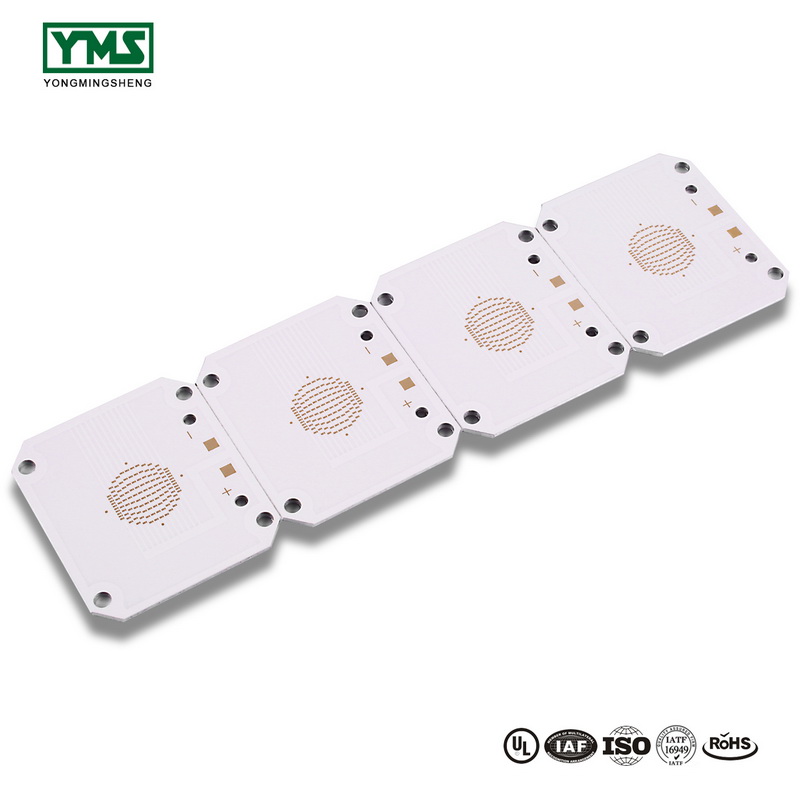

High Quality Fpc - 1Layer Aluminum base Board | YMSPCB – Yongmingsheng

High Quality Fpc - 1Layer Aluminum base Board | YMSPCB – Yongmingsheng Detail:

Aluminum base Board production process

- Laminate Shear and drill.

- Dry or wet pattern imaging.

- Acid or alkaline etching.

- Solder mask and silk screen.

- V – CUT and final shaping

- Electrical Test and Osp

- Check up case ,packing and shipping

You May Like:

1、How is aluminum base board cleaned during processing?

2、Important characteristics of high reliability industrial aluminum base board

3、Advantages and disadvantages, USES and differences of aluminum substrate and glass fiber board!

Product detail pictures:

Related Product Guide:

High Density Interconnect(HDI) PCBs Market Trends, Developments, Opportunities, Manufacture Size and Future Forecasts To 2024 | 1.2m 2layer Led Pcb

Global PCB & PCBA Market Analysis, Demand, Size & Forecast 2019-2025: Nippon Mektron, Unimicron, SEMCO, Young Poong Group, Ibiden, ZDT, Tripod, TTM, SEI | Fingerprint Lock Rigid-Flexible Pcb

"Control the quality by the details, show the strength by quality". Our company has strived to establish a highly efficient and stable staff team and explored an effective quality control process for High Quality Fpc - 1Layer Aluminum base Board | YMSPCB – Yongmingsheng , The product will supply to all over the world, such as: Greenland, Victoria, Tunisia, More than 26 years, Professional companies from all over the world take us as their long-term and stable partners. We are keeping durable business relationship with more than 200 wholesalers in Japan, Korea, USA, UK, Germany, Canada, France, Italian, Poland, South Africa, Ghana, Nigeria etc.

This is a honest and trustworthy company, technology and equipment are very advanced and the prodduct is very adequate, there is no worry in the suppliment.

Write your message here and send it to us