High definition Copper Base Board - Ceramic PCB single and double sided ceramics PCB manufacture Ceramic Substrates| YMS PCB – Yongmingsheng

High definition Copper Base Board - Ceramic PCB single and double sided ceramics PCB manufacture Ceramic Substrates| YMS PCB – Yongmingsheng Detail:

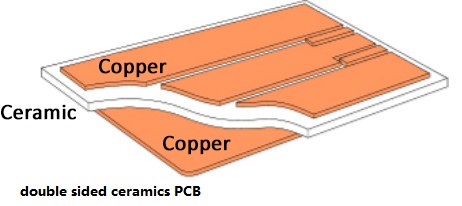

Ceramic PCB: ceramic substrate circuit board

Ceramic PCB is a kind of heat conducting ceramic powder and organic binder, and the heat conduction organic ceramic PCB is prepared at a thermal conductivity of 9-20W/m. In other words, ceramic PCB is a printed circuit board with ceramic base material, which is highly thermally conductive materials such as alumina, aluminum nitride, as well as beryllium oxide, which can make a quick effect on transferring heat away from hot spots and dissipating it over the whole surface. What’s more, ceramic PCB is fabricated with LAM technology, which is a laser rapid activation metallization technology. So ceramic PCB is highly versatile that can take place of the entire traditional printed circuit board with a less complicated construction with enhanced performance.

Apart from MCPCB, if you want to use PCB in high pressure, high insulation, high frequency, high temperature, and high reliable and minor volume electronic products, then Ceramic PCB will be your best choice.

Why Ceramic PCB has such excellent performance? You can have a brief view on its basic structure and then you will understand.

- 96% or 98% Alumina (Al2O3), Aluminum Nitride (ALN), or Beryllium Oxide (BeO)

- Conductors material: For thin, thick film technology, it’ll be silver palladium (AgPd), gold pllladium (AuPd); For DCB (Direct Copper Bonded) it’ll be copper only

- Application temp: -55~850C

- Thermal conductivity value: 24W~28W/m-K (Al2O3); 150W~240W/m-K for ALN , 220~250W/m-K for BeO;

- Max compression strength: >7,000 N/cm2

- Breakdown Voltage (KV/mm): 15/20/28 for 0.25mm/0.63mm/1.0mm respectively

- Thermal expansion conefficient(ppm/K): 7.4 (under 50~200C)

Types of ceramic PCBs

1. High temperature ceramic PCB

2. Low temperature ceramic PCB

3.Thick film ceramic PCB

YMS Ceramic PCB manufacturing capabilities:

| YMS Ceramic PCB manufacturing capabilities overview | ||

| Feature | capabilities | |

| Layer Count | 1-2L | |

| Material and Thickness | Al203: 0.15, 0.38,0.5,0.635,1.0,1.5,2.0mm etc. | |

| SIN: 0.25,0.38,0.5,1.0mm etc. | ||

| AIN: 0.15, 0.25,0.38,0.5,1.0mm etc. | ||

| Thermal conductivity | Al203: Min. 24 W/m.k up to 30W/m.k | |

| SIN: Min. 85 W/m.k up to 100W/m.k | ||

| AIN: Min. 150 W/m.k up to 320 W/m.k | ||

| Al2O3 | Al2O3 has better light reflectivity – making it suited for LED products. | |

| SIN | SiN has a very low CTE. Coupled with a high Rupture Strength it can withstand stronger thermal shock. | |

| AlN | AlN has superior Thermal Conductivity – making it suitable for very high power applications requiring the best possible thermal substrate. | |

| Board Thickness | 0.25mm-3.0mm | |

| copper Thickness | 0.5-10OZ | |

| Minimum line Width and Space | 0.075mm/0.075mm(3mil/3mil) | |

| Speciality | Countersink,Counterbore drilling.etc. | |

| Min mechanical Drilled Size | 0.15mm(6mil) | |

| Conductors material: | For thin, thick film technology, it’ll be silver palladium (AgPd), gold pllladium (AuPd),Platinum For DCB (Direct Copper Bonded) it’ll be copper only | |

| Surface Finish | HASL, Lead free HASL,ENIG,Immersion Tin, OSP, Immersion Silver, Gold Finger, Electroplating Hard Gold, Selective OSP,ENEPIG.etc. | |

| Solder Mask | Green, Red, Yellow, Blue, White, Black, Purple, Matte Black, Matte green.etc. | |

| polished | Ra < 0.1 um | |

| lapped | Ra < 0.4 um | |

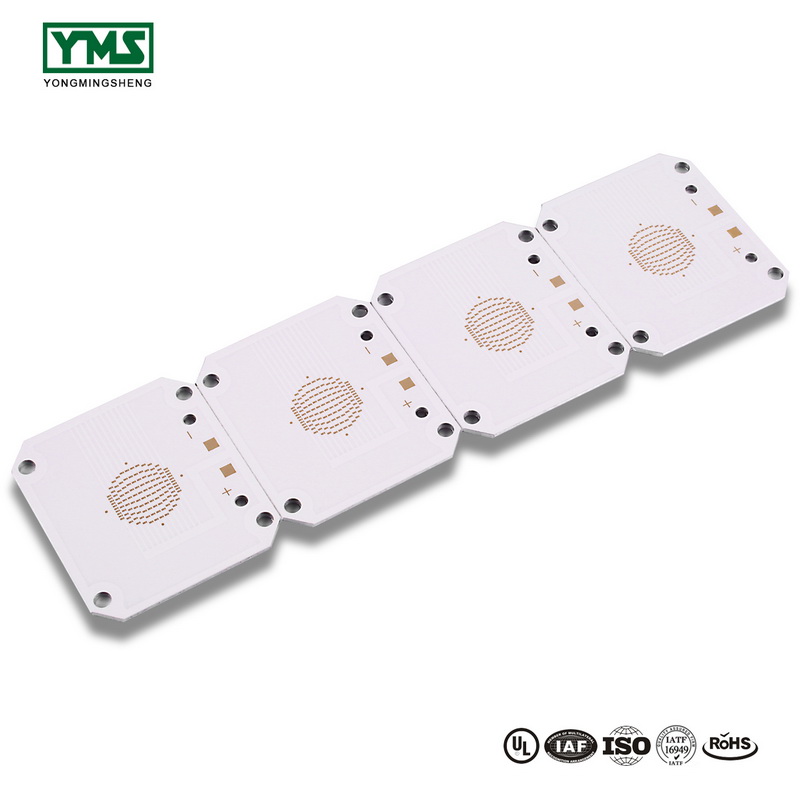

Product detail pictures:

Related Product Guide:

High-Density Interconnect (HDI) PCB Market Growth 2018-2025 | Hdi Pcb

General Micro Systems Launches Apex, the Highest Performance Upgradeable Secure Server under ITAR Control | Rigid-Flexible Pcb

"Based on domestic market and expand abroad business" is our enhancement strategy for High definition Copper Base Board - Ceramic PCB single and double sided ceramics PCB manufacture Ceramic Substrates| YMS PCB – Yongmingsheng , The product will supply to all over the world, such as: Austria, Mali, Uzbekistan, Honest to every customers are our requested! First-class serve, best quality, best price and fastest delivery date is our advantage! Give every customers good serve is our tenet! This makes our company get the favour of customers and support! Welcome all over the world customers send us enquiry and looking forward your good co-operation !Please your inquiry for more details or request for dealership in selected regions.

The company has rich resources, advanced machinery, experienced workers and excellent services, hope you keep improving and perfecting your products and service, wish you better!