High definition China Shenzhen Electronics Multilayer OEM/ODM PCB/PCBA, Manufacturing of Printed Circuit Board

Quality First,and Customer Supreme is our guideline to provide the best service to our customers.Nowadays, we are trying our best to become one of the best exporters in our field to meet customers more need for High definition China Shenzhen Electronics Multilayer OEM/ODM PCB/PCBA, Manufacturing of Printed Circuit Board, Hope we can create a more glorious future with you through our efforts in the future.

Quality First,and Customer Supreme is our guideline to provide the best service to our customers.Nowadays, we are trying our best to become one of the best exporters in our field to meet customers more need for China Printed Circuit Board, Circuit Board, We also have good cooperation relationships with many good manufacturers so that we can give almost all of auto parts and after-sales service with high quality standard,lower price level and warmly service to meet demands of customers from different fields and different area.

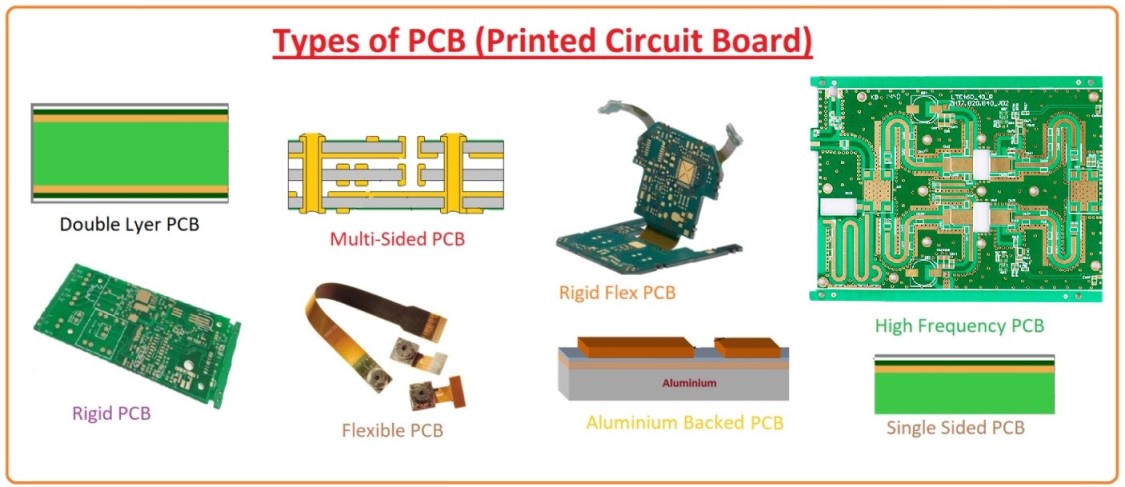

Printed Circuit Board Introduction

A printed circuit board (PCB) mechanically supports and electrically connects electrical or electronic components using conductive tracks, pads and other features etched from one or more sheet layers of copper laminated onto and/or between sheet layers of a non-conductive substrate. Components are generally soldered onto the PCB to both electrically connect and mechanically fasten them to it.PCBs can be single-sided (one copper layer), double-sided (two copper layers on both sides of one substrate layer), or multi-layer (outer and inner layers of copper, alternating with layers of substrate). Multi-layer PCBs allow for much higher component density, because circuit traces on the inner layers would otherwise take up surface space between components. The rise in popularity of multilayer PCBs with more than two, and especially with more than four, copper planes was concurrent with the adoption of surface mount technology.

YMS Normal PCB manufacturing capabilities:

| YMS Normal PCB manufacturing capabilities overview | ||

| Feature | capabilities | |

| Layer Count | 1-60L | |

| Available Normal PCB Technology | Through hole with Aspect Ratio 16:1 | |

| buried and blind via | ||

| Hybrid | High Frequency Material such as RO4350B and FR4 Mix etc. | |

| High Speed Material such as M7NE and FR4 Mix etc. | ||

| Material | CEM- | CEM-1;CEM-2;CEM-4;CEM-5.etc |

| FR4 | EM827, 370HR, S1000-2, IT180A, IT158, S1000 / S1155, R1566W, EM285, TU862HF,NP170G etc. | |

| High Speed | Megtron6, Megtron4, Megtron7,TU872SLK, FR408HR,N4000-13 Series,MW4000,MW2000,TU933 etc. | |

| High Frequency | Ro3003, Ro3006, Ro4350B, Ro4360G2, Ro4835, CLTE, Genclad, RF35, FastRise27 etc. | |

| Others | Polyimide, Tk, LCP, BT, C-ply, Fradflex, Omega , ZBC2000,PEEK,PTFE,ceramic-based etc. | |

| Thickness | 0.3mm-8mm | |

| Max.copper Thickness | 10OZ | |

| Minimum line Width and Space | 0.05mm/0.05mm(2mil/2mil) | |

| BGA PITCH | 0.35mm | |

| Min mechanical Drilled Size | 0.15mm(6mil) | |

| Aspect Ratio for through hole | 16:1 | |

| Surface Finish | HASL, Lead free HASL,ENIG,Immersion Tin, OSP, Immersion Silver, Gold Finger, Electroplating Hard Gold, Selective OSP,ENEPIG.etc. | |

| Via Fill Option | The via is plated and filled with either conductive or non-conductive epoxy then capped and plated over(VIPPO) | |

| Copper filled, silver filled | ||

| Registration | ±4mil | |

| Solder Mask | Green, Red, Yellow, Blue, White, Black, Purple, Matte Black, Matte green.etc. | |