Hoʻokumu ʻia nā PCB Ceramic me kahi substrate seramika, kahi papa pili, a me kahi papa kaapuni. ʻAʻole like me ka MCPCB, ʻaʻohe papa insulation nā PCB ceramic , a paʻakikī ka hana ʻana i ka papa kaapuni ma ka substrate ceramic. Pehea e hana ʻia ai nā PCB seramika? Ma muli o ka hoʻohana ʻia ʻana o nā mea seramika e like me nā substrate PCB, ua hoʻomohala ʻia kekahi mau ala e hana ai i ka papa kaapuni ma kahi substrate seramika. ʻO kēia mau ʻano ʻo HTCC, DBC, kiʻiʻoniʻoni mānoanoa, LTCC, kiʻiʻoniʻoni lahilahi, a me DPC.

HTCC

Pros: kiʻekiʻe structural ikaika; kiʻekiʻe thermal conductivity; paʻa kemika maikaʻi; kiʻekiʻe uwea haʻahaʻa; RoHS hōʻoia

Cons: maikaʻi ʻole conductivity kaapuni; kiʻekiʻe sintering wela; kumukūʻai pipiʻi

ʻO ka HTCC kahi pōkole o ke kiʻekiʻe-mehana co-fired ceramic. ʻO ia ke ʻano hana hana PCB ceramic mua loa. ʻO nā mea seramika no ka HTCC he alumina, mullite, a i ʻole alumini nitride.

ʻO kāna hana hana:

Ma 1300-1600 ℃, hoʻopaʻa ʻia ka pauka ceramic (me ka ʻole o ke aniani i hoʻohui ʻia) a maloʻo e paʻa. Inā makemake ka hoʻolālā ma nā puka, e wili ʻia nā puka ma ka papa substrate.

Ma nā wela kiʻekiʻe hoʻokahi, hoʻoheheʻe ʻia ka metala hoʻoheheʻe kiʻekiʻe e like me ka paʻi metala. Hiki i ka metala ke tungsten, molybdenum, molybdenum, manganese, a pēlā aku. Hiki i ka metala ke tungsten, molybdenum, molybdenum, a me ka manganese. Paʻi ʻia ka paʻi metala e like me ka hoʻolālā e hana i kahi papa kaapuni ma ka substrate kaapuni.

A laila, hoʻohui ʻia ka 4%-8% kōkua sintering.

Inā he multilayer ka PCB, ua laminated nā papa.

A laila ma 1500-1600 ℃, hoʻopili ʻia ka hui holoʻokoʻa e hana i nā papa kaapuni seramika.

ʻO ka hope, ua hoʻohui ʻia ka solder mask e pale i ka papa kaapuni.

Hana ʻia ʻo PCB kiʻiʻoniʻoni lahilahi

Pros: haʻahaʻa hana wela; kaapuni maikai; palahalaha ili maikai

Cons: nā lako hana pipiʻi; ʻaʻole hiki ke hana i nā ʻāpana ʻekolu

ʻO ka papa keleawe ma ka PCB kiʻi ʻoniʻoni ʻeleʻele he liʻiliʻi ka mānoanoa ma mua o 1mm. ʻO nā mea seramika nui no nā PCB seramika kiʻiʻoniʻoni he alumina a me ka nitride aluminika. ʻO kāna hana hana:

Hoʻomaʻemaʻe mua ʻia ka substrate ceramic.

I loko o nā kūlana vacuum, ua hoʻoheheʻe ʻia ka wai ma luna o ka substrate ceramic.

A laila, hoʻokumu ʻia kahi papa keleawe ma ka ʻili o ka substrate seramika e ka magnetron sputtering.

Hoʻokumu ʻia ke kiʻi kaapuni ma ka papa keleawe e ka ʻenehana photoresist māmā melemele.

A laila wehe ʻia ke keleawe nui loa e ka etching.

ʻO ka hope, hoʻohui ʻia ka solder mask e pale i ke kaapuni.

Hōʻuluʻulu manaʻo: ua hoʻopau ʻia ka hana ʻana o ka PCB kiʻi ʻoniʻoni ʻoniʻoni i loko o ke kūlana vacuum. Hiki i ka ʻenehana lithography māmā melemele ke ʻoi aku ka pololei i ke kaapuni. Eia nō naʻe, ʻo ka hana kiʻiʻoniʻoni lahilahi he palena i ka mānoanoa keleawe. He kūpono nā PCB seramika kiʻiʻoniʻoni kiʻekiʻe no ka paʻi kiʻekiʻe a me nā mea hana i kahi liʻiliʻi liʻiliʻi.

DPC

Pono: ʻaʻohe palena i ke ʻano keramika a me ka mānoanoa; kaapuni maikai; haʻahaʻa hana wela; palahalaha ili maikai

Cons: nā lako hana pipiʻi

ʻO DPC ka pōkole o ke keleawe paʻa pololei. Hoʻoulu ia mai ke ʻano hana ceramic kiʻiʻoniʻoni lahilahi a hoʻomaikaʻi ʻia ma ka hoʻohui ʻana i ka mānoanoa keleawe ma o ka plating. ʻO kāna hana hana:

ʻO ke kaʻina hana like o ka hana kiʻiʻoniʻoni lahilahi a paʻi ʻia ke kiʻi kaapuni ma ke kiʻi keleawe.

Hoʻohui ʻia ka mānoanoa keleawe kaapuni e ka hoʻopalapala ʻana.

Wehe ʻia ke kiʻi keleawe.

ʻO ka hope, hoʻohui ʻia ka solder mask e pale i ke kaapuni.

Ka hopena

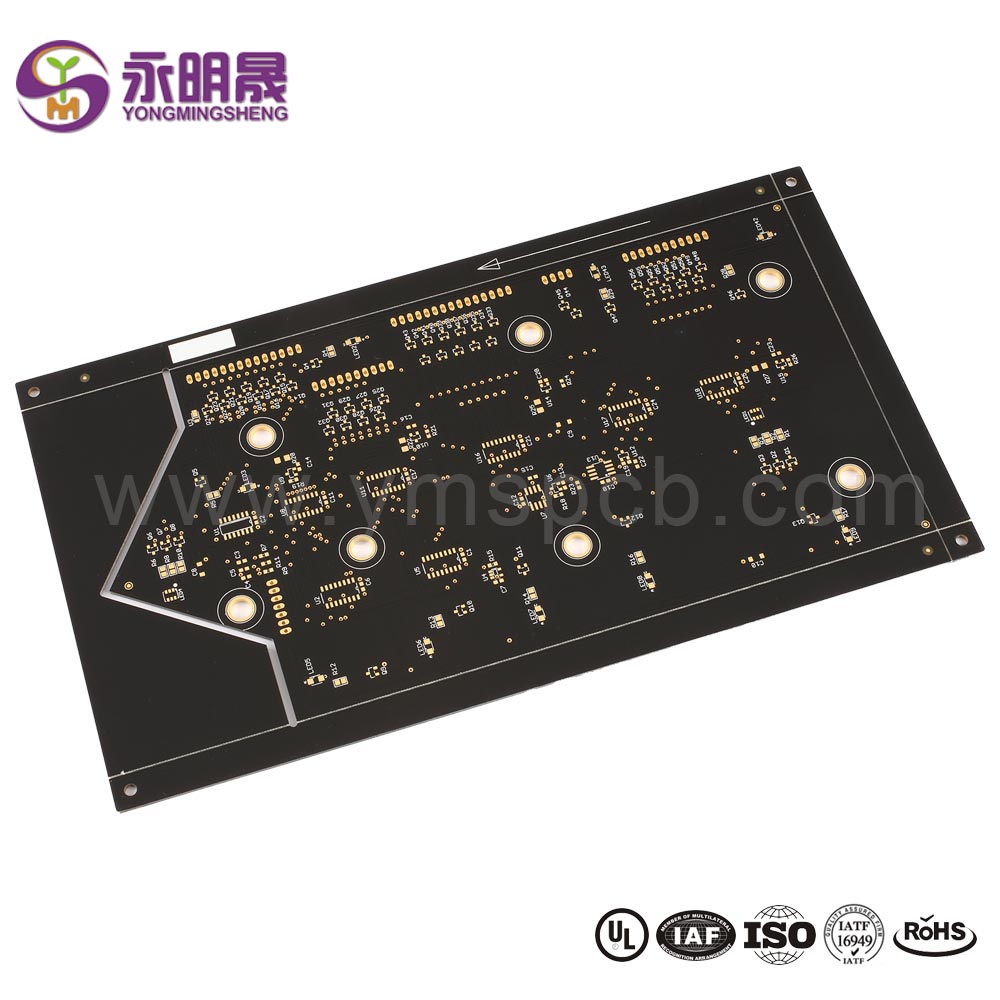

Hōʻike kēia ʻatikala i nā ʻano hana hana PCB ceramic maʻamau. Hoʻopuka ia i nā kaʻina hana hana PCB ceramic a hāʻawi i kahi loiloi pōkole o nā ʻano. Inā makemake nā ʻenekinia/nā ʻoihana hoʻonā / institute e hana ʻia a hui pū ʻia nā PCB seramika, e lawe mai ʻo YMSPCB iā 100% i nā hopena ʻoluʻolu iā lākou.

wikiō

E aʻo hou aʻe e pili ana i nā huahana YMS

Ka manawa hoʻouna: Feb-18-2022