Idan PCB yana da ƙarin ƙasa, akwai SGND, AGND, GND, da dai sauransu, dangane da matsayi na PCB surface , ana amfani da babban "ƙasa" a matsayin ma'anar ma'anar murfin jan karfe mai zaman kanta, wato, an haɗa ƙasa tare da juna. .

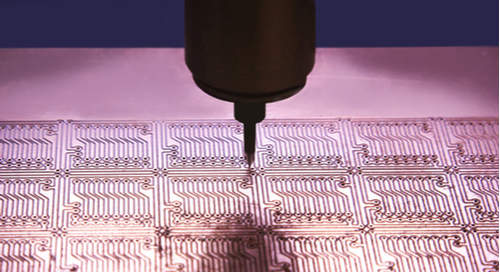

Tsarin Rushewar Tagulla

Cikakkun tsarin ta-in-pad na buƙatar ta ramuka a yi tagulla da tagulla domin tafiyar da sigina tsakanin yadudduka a PCB multilayer. Wannan platin yana haɗawa da wasu pads a cikin tsarin ta-in-pad, da kuma kai tsaye zuwa alamar ta amfani da ƙaramin zobe na annular. Waɗannan gine-ginen ba makawa ne, amma an san suna da wasu matsalolin dogaro a ƙarƙashin maimaita hawan keke.

Ma'auni na IPC 6012E kwanan nan sun ƙara buƙatun kunsa na jan karfe zuwa tsarin ta-in-pad. Cikakkun platin jan karfe ya kamata ya ci gaba a kusa da gefen ramin kuma ya mika kan zoben annular da ke kewaye da kushin. Wannan buƙatun yana inganta amincin ta hanyar plating kuma yana da yuwuwar rage gazawar saboda fashe, ko kuma saboda rabuwa tsakanin sifofin saman da plated ta rami.

Cikakkun tsarin kunsa na tagulla suna bayyana a cikin nau'i biyu. Na farko, ana iya amfani da fim ɗin jan karfe mai ci gaba da yin amfani da shi a cikin ta hanyar, wanda sannan ya nannade saman saman da kasa yadudduka a ƙarshen ta. Wannan kunsa na jan karfe sannan ya samar da ta hanyar kushin da alamar da ke kaiwa ga hanyar, samar da tsari mai ci gaba da jan karfe.

A madadin haka, via na iya samun nasa kushin da aka kafa a kusa da ƙarshen hanyar. Wannan keɓantaccen Layer na pad yana haɗawa da alamu ko jiragen ƙasa. Platin jan karfe wanda ya cika ta hanyar sai ya nannade saman saman wannan pad na waje, yana samar da haɗin gwiwa tsakanin platin tagulla da ta pad. Wasu haɗin gwiwa yana faruwa tsakanin cika plating da ta pad, amma su biyun ba sa haɗawa tare kuma ba sa samar da tsari guda ɗaya mai ci gaba.

Akwai dalilai da yawa don sanya tagulla:

1. EMC. Don babban yanki na ƙasa ko ƙarfin jan ƙarfe, zai yi garkuwa, da wasu na musamman, kamar PGND don karewa.

2. PCB tsari bukatun. Gabaɗaya, don tabbatar da tasirin plating, ko laminate ɗin bai lalace ba, an shimfiɗa jan ƙarfe don Layer na PCB tare da ƙarancin wayoyi.

3. Bukatun amincin sigina, ba da siginar siginar siginar siginar sigina mai ƙarfi cikakkiyar hanyar dawowa, da rage wayoyi na cibiyar sadarwar DC. Tabbas, akwai zubar da zafi, shigarwa na na'ura na musamman yana buƙatar platin jan karfe da sauransu.

Babban fa'ida na platin jan ƙarfe shine don rage ƙarancin layin ƙasa (abin da ake kira tsangwama kuma yana haifar da babban ɓangare na rage ƙarancin layin ƙasa). Akwai igiyoyin karu da yawa a cikin da'irar dijital, don haka ya fi zama dole don rage ƙarancin layin ƙasa. An yi imani da cewa da'irori da suka ƙunshi na'urorin dijital gabaɗaya ya kamata a yi ƙasa a kan wani babban yanki, kuma ga na'urorin analog, madauki na ƙasa da aka yi ta hanyar platin jan karfe na iya haifar da tsangwama na haɗin gwiwar lantarki ya zama ƙasa (sai dai manyan da'irori). Saboda haka, ba da'ira ba ce dole ta zama tagulla (BTW: jan ƙarfe jan ƙarfe ya fi duka block).

Muhimmancin daftarin jan ƙarfe:

1. jan karfe da waya na ƙasa da aka haɗa, wannan zai iya rage yankin madauki

2. Babban yanki na platin jan karfe yana daidai da rage juriya na waya ta ƙasa, rage raguwar matsa lamba daga waɗannan maki biyu An ce duka filin dijital da filin analog ya kamata su zama tagulla don ƙara ƙarfin hana tsoma baki, kuma a manyan mitoci, filin dijital da filin analog ya kamata a ware su shimfiɗa tagulla, sa'an nan kuma a haɗa su da maki ɗaya, wurin guda ɗaya zai iya amfani da waya don yin ƴan kunnawa a kan zoben maganadisu sannan a haɗa. Duk da haka, idan mitar ba ta da yawa, ko yanayin aiki na kayan aiki ba su da kyau, za ku iya shakata sosai. Ana iya ƙidaya crystal a matsayin tushen mai girma a cikin kewaye. Kuna iya sanya tagulla a kusa da ƙasa da kristal, wanda ya fi kyau.

Idan kuna sha'awar ƙarin koyo game da YMS PCB, tuntuɓe mu a kowane lokaci.

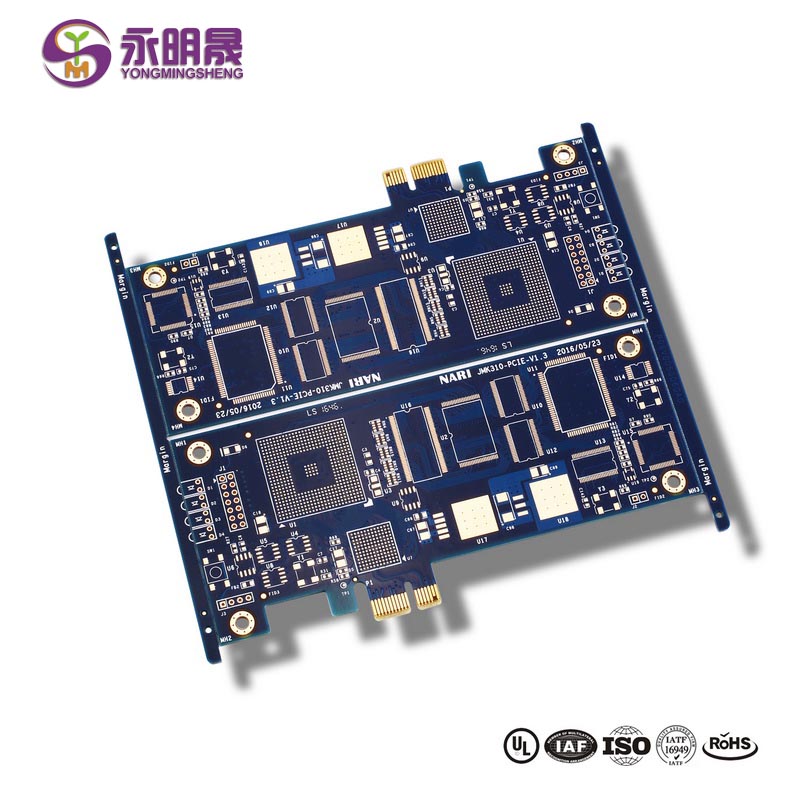

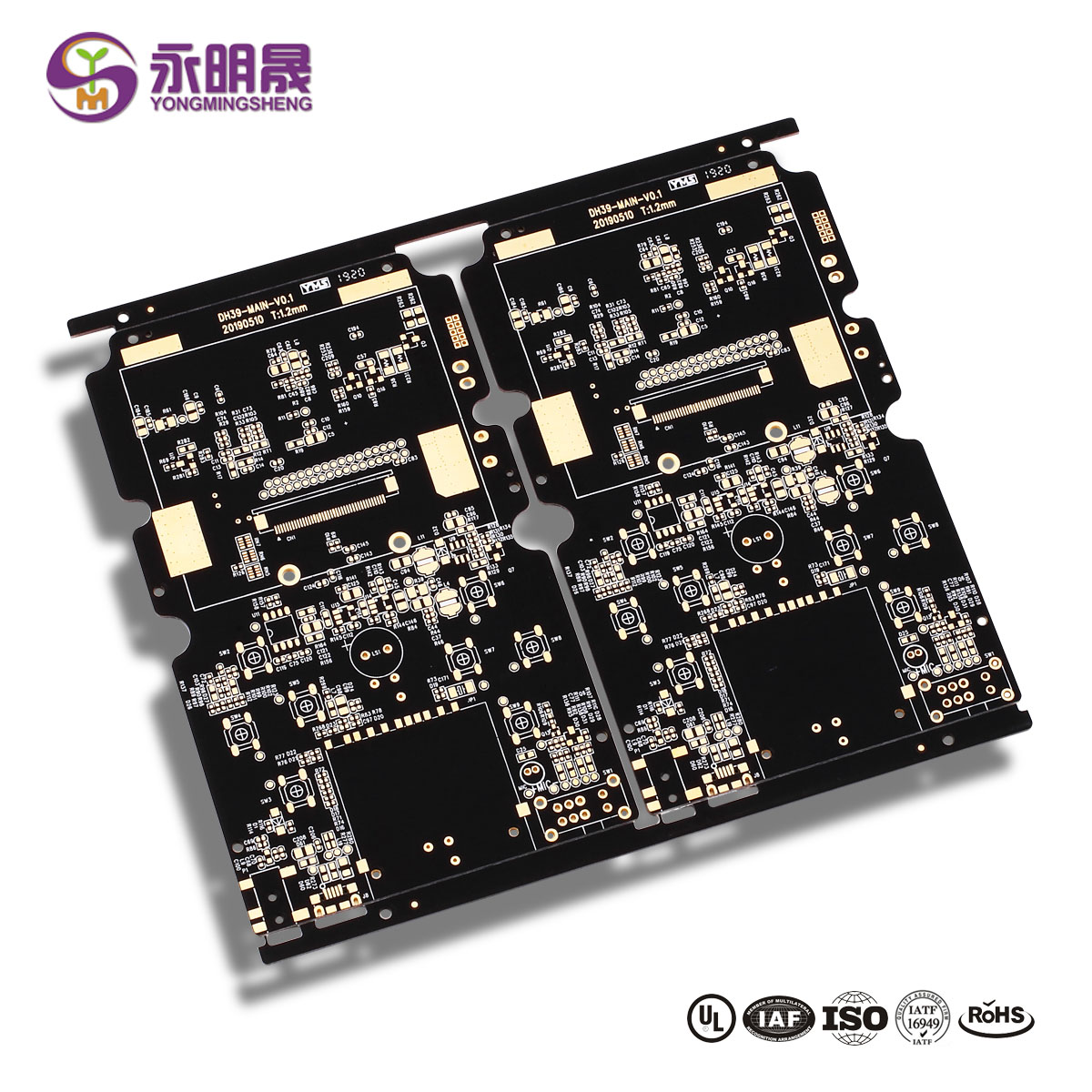

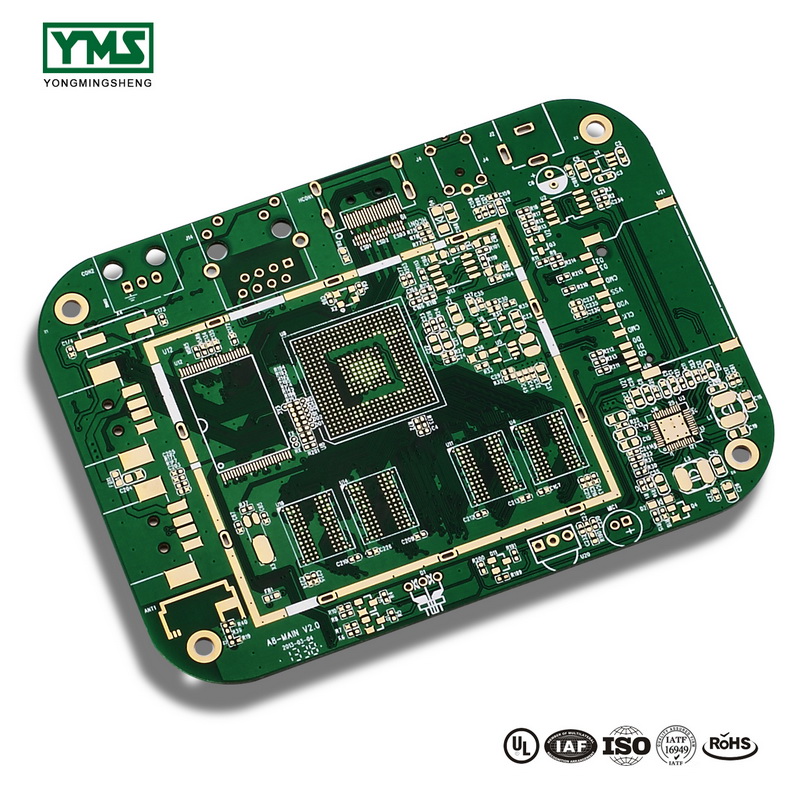

Ƙara koyo game da samfuran YMS

Mutane kuma suna tambaya

Lokacin aikawa: Afrilu-08-2022