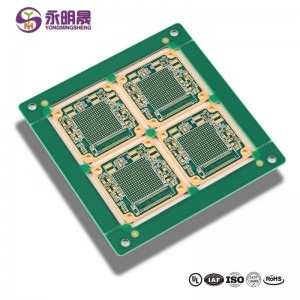

Edge Plating PCB 10 Layer Board gefen plating PCB| Farashin YMS PCB

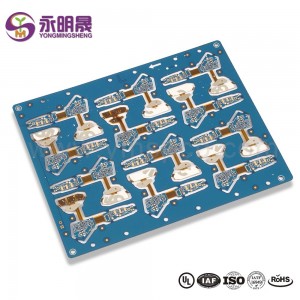

Menene PCB Edge Plating?

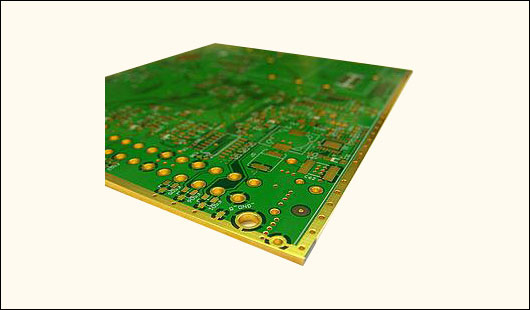

PCB gefen plating shine tsarin haɗa sama da ƙasan PCB ta hanyar yin amfani da lantarki a kusa da gefuna na PCB. Wannan tsari kuma za a iya sanya masa suna azaman sideplating, plating na iyaka, ƙera ƙarfe, ko kwane-kwane. Don na'urori masu matsakaici ko manyan buƙatu don EMC, amincin sigina, da ɓarkewar zafi, ɓangarorin gefen yana da fa'idodi na fa'ida a farashi mara kyau. Yawancin lokaci, ENIG ko nickel-zinariya ana ba da shawarar su zama hanyar gamawa ta fuskar bangon.

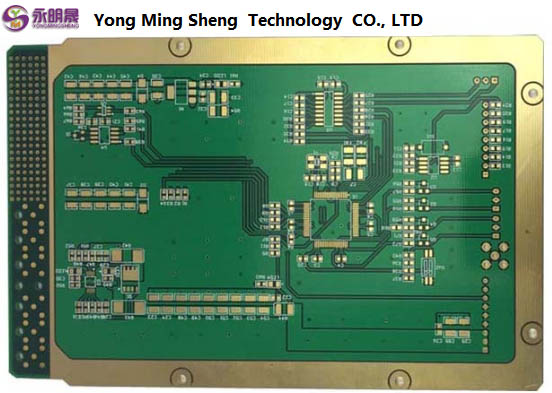

EDGE PLATING TSARIN PCB

Ƙirƙirar allon da'ira da aka buga don siyar da gefuna yana buƙatar daidaitaccen kulawa kuma yana fuskantar ƙalubale da yawa dangane da yadda ake shirya gefuna da mannewar rayuwar kayan da aka yi.

MCL ya kafa ayyukan masana'antu da kerawa zuwa waɗannan ka'idoji don tabbatar da cewa kas ɗin yana shirya saman gefuna sosai, yana amfani da jan ƙarfe da aka ɗora don mannewa kai tsaye da aiwatar da jirgi don tabbatar da mannewa na kowane Layer na dogon lokaci.

By using a controlled process in our circuit board fabrication for edge soldering, we can limit any potential hazard for through-holes and half-holes on the edge. The most significant concern is the creation of burrs, which will lead to the failure of mission-critical parts and can damage your equipment.

APPLICATIONS

Allolin da'irar da'ira sun zama ruwan dare gama gari a masana'antu da yawa, kuma yin gyare-gyaren gefe abu ne na kowa. Za ku sami PCB baki castelation (ko gefen plating PCBs) ana amfani da su a lokuta da yawa, gami da:

Haɓaka iya ɗaukan halin yanzu

Haɗin haɗin gwiwa da kariya

Siyar da gefen don inganta ƙirƙira

Ingantacciyar goyan baya don haɗin kai kamar allon da ke zamewa cikin kwandon ƙarfe

Da fatan za a lura cewa ɗora gefuna akan allunan da'ira bugu abu ne mai sauƙi ƙari a lokuta da yawa, amma yana buƙatar kayan aiki na musamman da horo. Zabi ne na alluna daban-daban, amma koyaushe muna ba da shawarar ɗaukar irin wannan buƙatun ga masana'anta, kamar MCL, wanda ke da ƙaƙƙarfan ƙaƙƙarfan ƙaƙƙarfan ƙa'idar hukumar da'ira.

Za mu iya yin daidaitaccen binciken injiniya don kiyaye komai lafiya. Misali, kasuwar allon kewayawa bai kamata ya sa jiragen saman wutar lantarki na ciki su zo bakin allon ba, domin yana iya takaita platin gefen. Lokacin da kuke tafiya, koyaushe ku kula da gibin. Lokacin da muke yin ƙirar allon kewayawa don siyar da gefuna, koyaushe muna tabbatar da akwai tazara kafin platin gefen. Edge plating yana taimakawa ƙirƙirar haɗin gwiwa mai ƙarfi na PCBs kuma yana iya rage damar gazawar na'urar. Sabili da haka, ana amfani da plating na gefe sosai a aikace-aikace inda ake buƙatar samun tallafi mafi kyau kuma ya zama al'ada ta gama gari a PCB na . YMS yana ba da kayan aiki na ƙwararru da ƙwararrun injiniyoyi don aiwatar da aikin shimfidar wuri. Da fatan za a aiko mana da imel ko tuntuɓi sabis ɗin mu na kan layi don ƙarin cikakkun bayanai game da tsarin saɓowar gefe da sigogin ƙira.

Iyakance

Saboda masu ƙirƙira suna buƙatar riƙe allunan kewayawa a cikin kwamitin samarwa a cikin samfur na PCb, ba za su iya yin cikakken tsayin gefen ba. Don haka, akwai wasu gibin da ake buƙata don sanya shafuka masu ɓarna. Yana buƙatar zazzage bayanan bayanan da'ira a wurin lokacin ƙirƙirar allunan kewayawa tare da plating gefuna , kuma ana buƙatar plating gefen kafin fara aiwatar da plating ta hanyar rami, wanda ke cire maƙirarin v-cut akan PCB wanda ke buƙatar sharar plating gefen. .

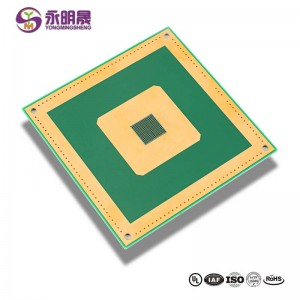

PCB a gefen YMS

Tare da fiye da shekaru 10 a matsayin jagoran masana'antu, YMS yana da ƙwarewar masana'antu don PCB gefen plating, kuma muna da ikon sarrafa babban inganci don plating baki ba tare da burrs ba. Saboda gamsuwar abokan ciniki shine burin mu, za mu yi ƙoƙari mu ƙirƙira hukumar ku tare da mafi girman inganci don biyan buƙatun ku kuma ku himmantu ga bin ƙaƙƙarfan ƙa'idodi a ƙirƙira da taro na PCB.

YMS, mafi kyawun abokin aikin injiniyan lantarki, yana ba ku ƙirƙirar PCB mai rahusa tare da inganci.

Kuna Iya So:

1. Yadda ake yin PCB mai girma

Bidiyo

Ƙara koyo game da samfuran YMS

Mene ne gefen plating a PCB?

Wataƙila kun ji wannan ra'ayi da ake kira "gefen plating" ko "castelation," wanda shine platin jan karfe wanda ke gudana daga sama zuwa saman saman PCB, kuma yana gudana tare da akalla ɗaya daga cikin gefuna. PCB gefen castelation yana tabbatar da haɗin gwiwa mai ƙarfi ta hanyar jirgi kuma yana iyakance damar gazawar kayan aiki, musamman a cikin sarrafa kariya ga ƙaramin allo mai ƙima da ƙaramin allo.

Menene platin jan karfe a PCB?

Plating Copper wani tsari ne na sinadarai na lantarki, wanda a cikinsa ake ajiye wani Layer na tagulla a saman ƙarfe na ƙarfe ta hanyar amfani da wutar lantarki.

Rufe tagulla abu ne mai mahimmanci saboda:

Yana ba da kariya ta lalata mai mahimmanci.

Yana inganta juriya na lalacewa.

Yana da kyau kwarai mannewa ga mafi tushe karafa, inganta ductility na rufi kayayyakin.

Yana da kyawawan halayen zafi da ƙarfin wutar lantarki, yana yin samfuran plated ɗin da suka dace da aikace-aikacen injiniya na daidaici, kamar allon da'ira (PCB).