Flex rigid Board semi flex PCB Black Soldermask| YMSPCB

What is Semi-Flex PCB?

It meast tradisjonele produksjeproses fan semi-flex PCB is it oannimmen fan de bûgende FR-4-materialen en it meitsjen fan PCB neffens it tradisjonele stive PCB-produksjeproses, en dan de djippe freestechnology brûke om de gebieten te dûnsjen dy't moatte wurde bûge, sadat it hat in beskate mjitte fan fleksibiliteit, om sa te foldwaan oan 'e easken fan ferbining foar gearstalling bûgjen.

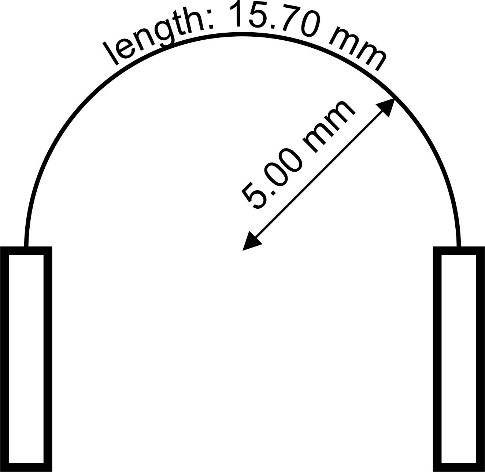

SEMI-FLEX lingte rekkenmasine: (2 x Π x bochtradius) x (bochtwinkel / 360 °)

Bygelyks, 5 kear bûge oer in hoeke fan 180 graden mei in straal fan 5 mm fereasket in minimale lingte fan it semi-flex diel fan 15,7 mm

YMS Semi-Flex PCB produksjekapaliteiten :

| YMS Semi-Flex PCB-produksjemooglikheden oersjoch | ||

| Eigenskip | mooglikheden | |

| Laach telle | 2-20L , mei 1 - 2 geleidende lagen yn it fleksibele diel | |

| Stiif-Flex dikte | 0.5mm-5.0mm | |

| PCB-dikte yn flex-seksje | 0,15-0,8 mm ± 0,05 mm | |

| koper Dikte | 1 / 4OZ-10OZ | |

| Minimale rigelbreedte en romte | 0.05mm / 0.05mm (2mil / 2mil) | |

| Stifters | Rustfrij stiel, PI, FR4, Aluminium ensfh. | |

| Materiaal | FR4, RA koper, HTE koper, lijm, Bondply , dekklaach, fleks soldermasker | |

| Min meganyske boarre Grutte | 0,15 mm (6mil) | |

| Min laser gatten Grutte: | 0,075mm (3mil) | |

| Oerflakte ôfwurking | Geskikt mikrofoave / RF-PCB-oerflakôfwurkingen: Elektroleaze nikkel, Immersion Gold, ENEPIG, Leadfrije HASL, Immersion Silver.etc. | |

| Solder Masker | Grien, read, giel, blau, wyt, swart, pears, mat swart, mat grien. Ensfh. | |

| Covrelay (Flex Part) | Giele omslach, Wyt omslach, Swarte omslach |

|

Learje mear oer YMS-produkten

Lês mear nijs

What is a rigid flex board?

The rigid-flex board is a flexible circuit board(FPC) and a rigid circuit board (PCB), which are combined together according to the relevant process requirements through pressing and other processes in the PCB proofing to form a circuit board with FPC characteristics and PCB characteristics.

What is difference between rigid and flexible boards?

As the names suggest, a rigid PCB is a circuit board built on a rigid base layer that cannot bend, while a flexible PCB, also called a flex circuit, is built on a flexible base capable of bending, twisting and folding.

Where are rigid flex PCBs used?

You’ll find them in commercial, industrial and military applications. From digital cameras to cell phones to smart devices, they serve them all. Especially in the medical industry for developing pacemakers for their weight reduction, space, and flexible capabilities.