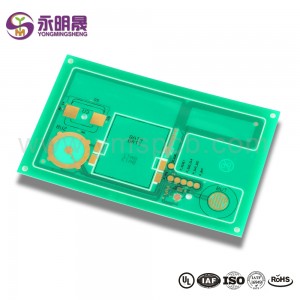

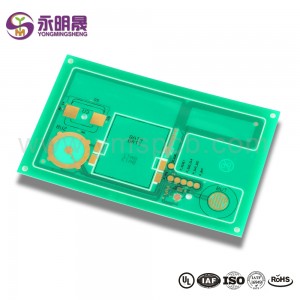

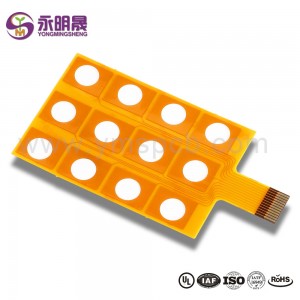

Flexible circuits help reduce the weight of finished electronics while allowing increased circuit density and eliminating cumbersome connections and wiring.The ability to fold flexible circuits extends the scope of design and packaging.

We offer a full range of products for the automotive, computer, communications, industrial and medical markets.

FPC Strengths

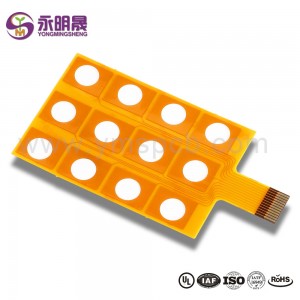

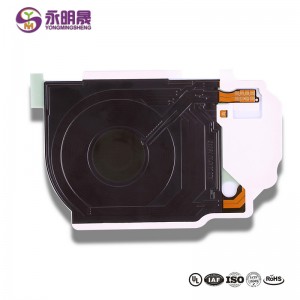

Flexibility:Stablity and repeatable flexibility are helpful for special forms of electronic assembly that can be designed into 3D structures

Toughness:Since the FPC has a certain toughness,the distance between contacts can be adjusted automatically according to the therma stress,and the risk of stress concentration at the connection point can be reduced

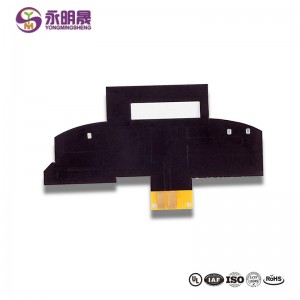

Thin dielectric layer:Thin dielectric layer has better flexibility and better heat transfer, which will be a benefit for structure design and thermal managenent

High temperatureperformance:PI material can be operated under high temperature and can fit for high temperature applications

Machinability:Some flexible materials can create pads or window by laser or chemical etch, which can be used for the application of two-sided assembly of single-layer copper foil

Interconnection,downsizing,weight reduction:The FPC can be flexed and 3D bent according to needs, and the rigid-flex board can reduce the noise and reliability of the terminal, thereby simplifying the connection and saving the the connector and the terminal, and the product weight is also reduced

Space utilization:Flexible boards can replace many point-to-point connection parts,connecting lines that can not be connected in different planes,thus simplifying design and increasing space utilization