Factory Supply 1050c Ceramic Board - Copper Base High Power (Metal core) Board | YMS PCB – Yongmingsheng

Factory Supply 1050c Ceramic Board - Copper Base High Power (Metal core) Board | YMS PCB – Yongmingsheng Detail:

The main reasons for using copper base boards

1. Good heat dissipation: At present, many 2 layer board and multilayer boards have the advantage of high density and high power, but the heat emission is difficult to be. Normal PCB base material such as FR4, CEM3 is a poor conductor of heat, insulation is between layers, and heat emission cannot go out. Local heating of electronic equipment cannot be eliminated will result in high-temperature failure of electronic components. But the good heat dissipation performance of metal core PCB can solve this heat dissipation problem.

2. Dimensional stability: Metal core PCB is obviously much more stable in size than printed boards of insulating materials. Aluminum base board and aluminum sandwich board is heating from 30℃ to 140~150℃, its size changes of 2.5~3.0%.

3. Other cause: Copper base board has shielding effect and replaces brittle ceramic substrate, so it can rest assured to use surface mounting technology to reduce the real effective area of PCB. Copper base board replaces the radiator and other components, improve the heat resistance and physical performance of products and it reduces production costs and labor costs.

1. Good heat dissipation: At present, many 2 layer board and multilayer boards have the advantage of high density and high power, but the heat emission is difficult to be. Normal PCB base material such as FR4, CEM3 is a poor conductor of heat, insulation is between layers, and heat emission cannot go out. Local heating of electronic equipment cannot be eliminated will result in high-temperature failure of electronic components. But the good heat dissipation performance of metal core PCB can solve this heat dissipation problem.

2. Dimensional stability: Metal core PCB is obviously much more stable in size than printed boards of insulating materials. Aluminum base board and aluminum sandwich board is heating from 30℃ to 140~150℃, its size changes of 2.5~3.0%.

3. Other cause: Copper base board has shielding effect and replaces brittle ceramic substrate, so it can rest assured to use surface mounting technology to reduce the real effective area of PCB. Copper base board replaces the radiator and other components, improve the heat resistance and physical performance of products and it reduces production costs and labor costs.

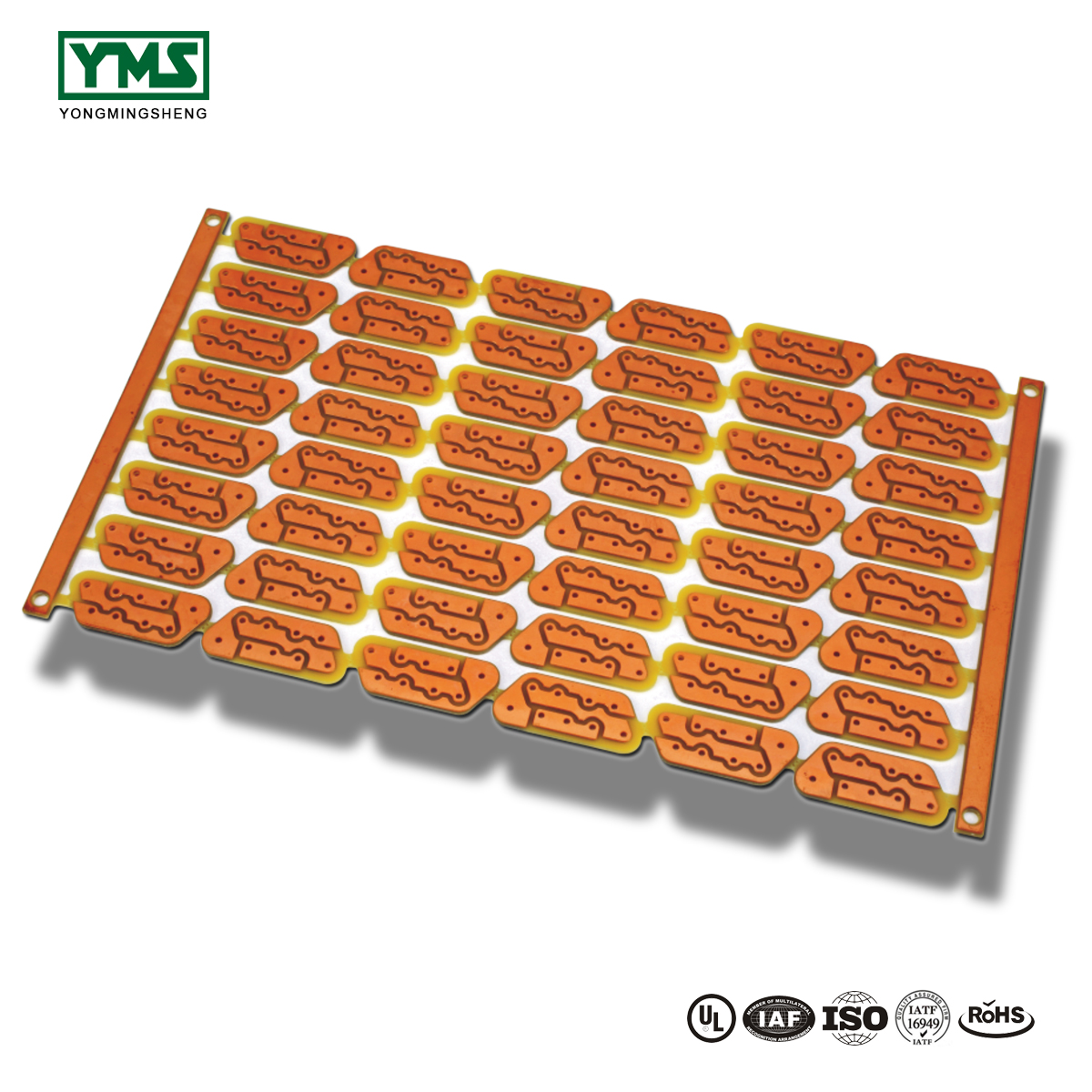

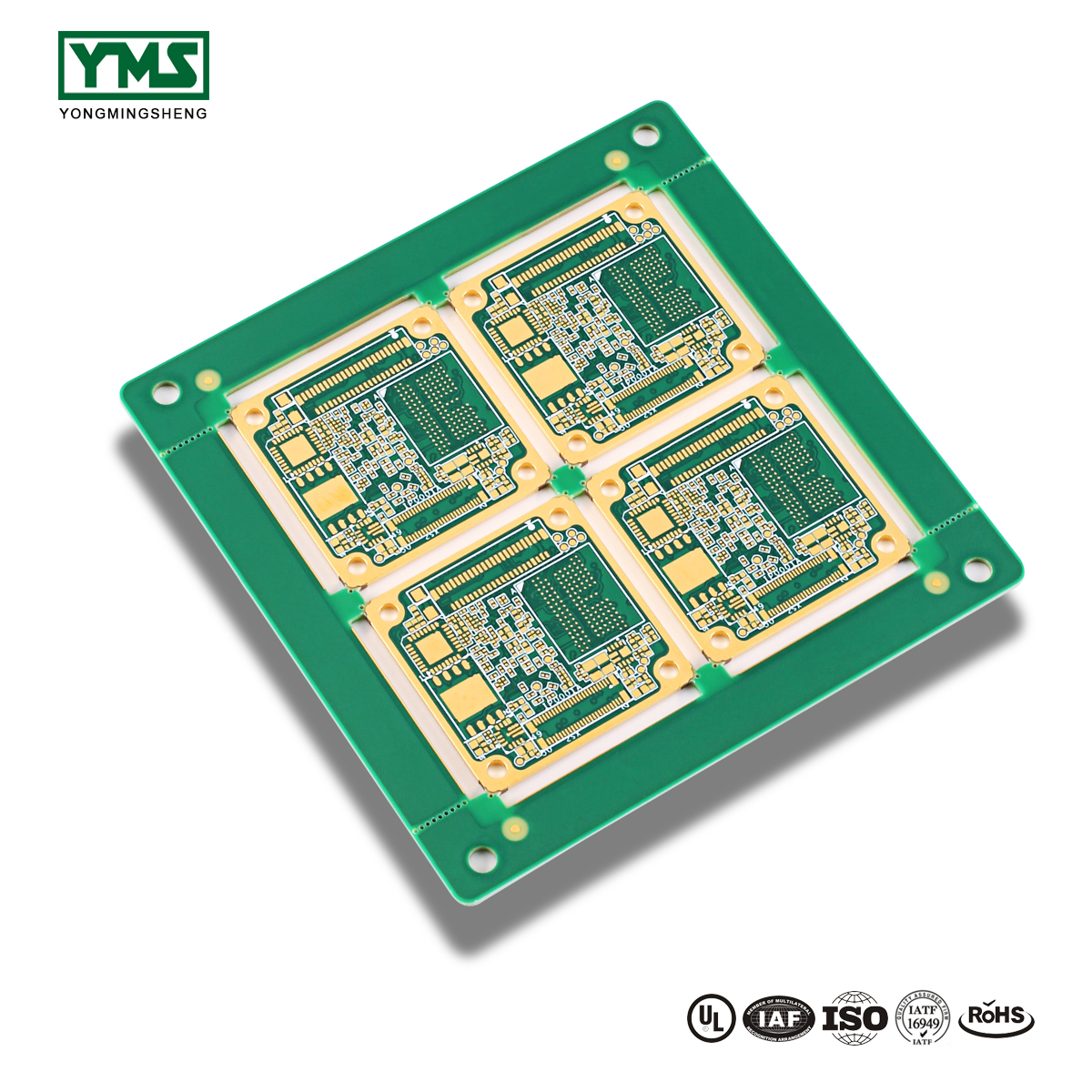

Product detail pictures:

Related Product Guide:

High Density Interconnect(HDI) PCBs Market Research Methodology Focuses On Exploring Major Factors Influencing the Industry Development 2023 key players IBIDEN Group, Unimicron, AT&S, SEMCO, NCAB Group, Young Poong Group, ZDT, Compeq, Unitech Printed Ci | 1.2m 2layer Led Pcb

Technical Safety BC highlights common causes of residential electrical fires | Copper Base Board

We constantly function like a tangible group to ensure that we can give you the very best high-quality and also the very best cost for Factory Supply 1050c Ceramic Board - Copper Base High Power (Metal core) Board | YMS PCB – Yongmingsheng , The product will supply to all over the world, such as: Netherlands, Bangalore, Mauritius, Many goods fully conform to the most rigorous of international guidelines and with our first-rate delivery service you will have them delivered at any time and in any place. And because Kayo deals in the entire spectrum of protective equipment, our customers don't have to waste time shopping around.

Staff is skilled, well-equipped, process is specification, products meet the requirements and delivery is guaranteed, a best partner!

Write your message here and send it to us