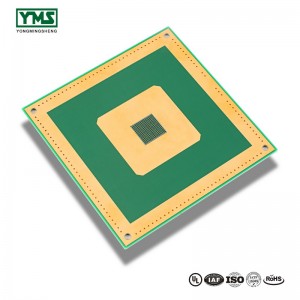

Factory Outlets Cti600 Hr-4600 Copper Clad Laminate Epoxy Fiber Glass Sheet Ccl For Pcb

With this motto in mind, we’ve come to be one of quite possibly the most technologically innovative, cost-efficient, and price-competitive manufacturers for Factory Outlets Cti600 Hr-4600 Copper Clad Laminate Epoxy Fiber Glass Sheet Ccl For Pcb, With a wide range, top quality, sensible price ranges and stylish designs,Our merchandise are widely recognized and dependable by users and can meet up with continuously changing economic and social needs.

With this motto in mind, we’ve come to be one of quite possibly the most technologically innovative, cost-efficient, and price-competitive manufacturers for Ccl, Copper Clad Laminate Pcb, Epoxy Glass Fabric Laminated Sheets, Our company absorbs new ideas, strict quality control, a full range of service tracking, and adhere to make high-quality products. Our business aims to “honest and trustworthy, favorable price, customer first”, so we won the trust of the majority of customers! If you are interested in our goods and services, please do not hesitate to contact us!

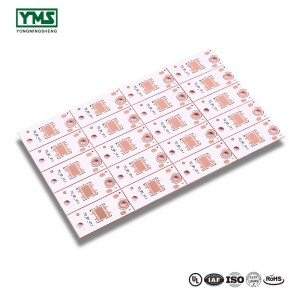

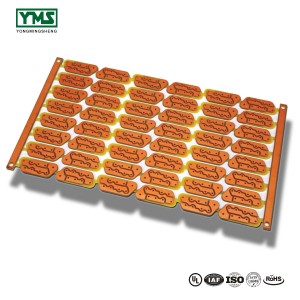

Thick copper plate basic production process:

A、The inner core plate is obtained by cutting materials, and the inner circuit is made on each inner core plate respectively through the processing of inner graph and etching. A number of copper pads are interleaved on the edge of the plate in the open area of each inner core plate to make each inner core plate.

B、The inner layer and outer layer of copper foil are pressed together by semi-curing sheet to make multi-layer production plate.

C、According to the existing technology, the thick copper plate is prepared by the post-treatment of the multilayer production plate.

Board2.jpg)

Board2-300x300.jpg)