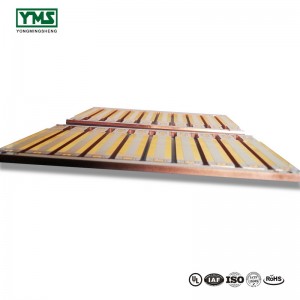

Factory directly 5kw Induction Heating System Pcb For Water Heater Pressure Cooker Hot Pot Tea Maker With Ic Inside

Well-run tools, expert profits crew, and much better after-sales products and services; We’ve been also a unified major spouse and children, every person stick to the company benefit “unification, dedication, tolerance” for Factory directly 5kw Induction Heating System Pcb For Water Heater Pressure Cooker Hot Pot Tea Maker With Ic Inside, We, with open up arms, invite all intrigued buyers to go to our web page or call us instantly for further more info.

Well-run tools, expert profits crew, and much better after-sales products and services; We’ve been also a unified major spouse and children, every person stick to the company benefit “unification, dedication, tolerance” for Heating Pcb, Induction Pcb, Inductive Pcb, “Good quality and reasonable price” are our business principles. If you are interested in our solutions or have any questions, remember to feel free to contact us. We hope to establish cooperative relationships with you in the near future.

For metal substrate, copper and aluminum are used in PCB, but have various applications;

However, if we discuss it from the Angle of the PCB Plating, we get a totally different answer:

PCB plating mainly includes copper, tin, nickel and gold plating.Copper plating is an important processing technology in PCB manufacturing.

As you know, copper plating has the advantages of good electrical conductivity, thermal conductivity, mechanical malleability and so on, namely, copper immersion after drilling, electroplating of the whole PCB, and thickening circuit with copper, all of which are to ensure electrical conductivity;In addition, ordinary plating solution is CuSO4;

In short, the process goes like this: drilling – immersion copper-plating – wire-drawing – etching

You May Like:

1、Understand the construction of heavy copper PCB

2、Common reasons for PCB to dump copper

3、PCB coated with copper knowledge tips

Board-300x300.jpg)

Board2-300x300.jpg)