Factory best selling Double Side Metal Core Pcb - Copper Base High Power (Metal core) Board | YMS PCB – Yongmingsheng

Factory best selling Double Side Metal Core Pcb - Copper Base High Power (Metal core) Board | YMS PCB – Yongmingsheng Detail:

The main reasons for using copper base boards

1. Good heat dissipation: At present, many 2 layer board and multilayer boards have the advantage of high density and high power, but the heat emission is difficult to be. Normal PCB base material such as FR4, CEM3 is a poor conductor of heat, insulation is between layers, and heat emission cannot go out. Local heating of electronic equipment cannot be eliminated will result in high-temperature failure of electronic components. But the good heat dissipation performance of metal core PCB can solve this heat dissipation problem.

2. Dimensional stability: Metal core PCB is obviously much more stable in size than printed boards of insulating materials. Aluminum base board and aluminum sandwich board is heating from 30℃ to 140~150℃, its size changes of 2.5~3.0%.

3. Other cause: Copper base board has shielding effect and replaces brittle ceramic substrate, so it can rest assured to use surface mounting technology to reduce the real effective area of PCB. Copper base board replaces the radiator and other components, improve the heat resistance and physical performance of products and it reduces production costs and labor costs.

1. Good heat dissipation: At present, many 2 layer board and multilayer boards have the advantage of high density and high power, but the heat emission is difficult to be. Normal PCB base material such as FR4, CEM3 is a poor conductor of heat, insulation is between layers, and heat emission cannot go out. Local heating of electronic equipment cannot be eliminated will result in high-temperature failure of electronic components. But the good heat dissipation performance of metal core PCB can solve this heat dissipation problem.

2. Dimensional stability: Metal core PCB is obviously much more stable in size than printed boards of insulating materials. Aluminum base board and aluminum sandwich board is heating from 30℃ to 140~150℃, its size changes of 2.5~3.0%.

3. Other cause: Copper base board has shielding effect and replaces brittle ceramic substrate, so it can rest assured to use surface mounting technology to reduce the real effective area of PCB. Copper base board replaces the radiator and other components, improve the heat resistance and physical performance of products and it reduces production costs and labor costs.

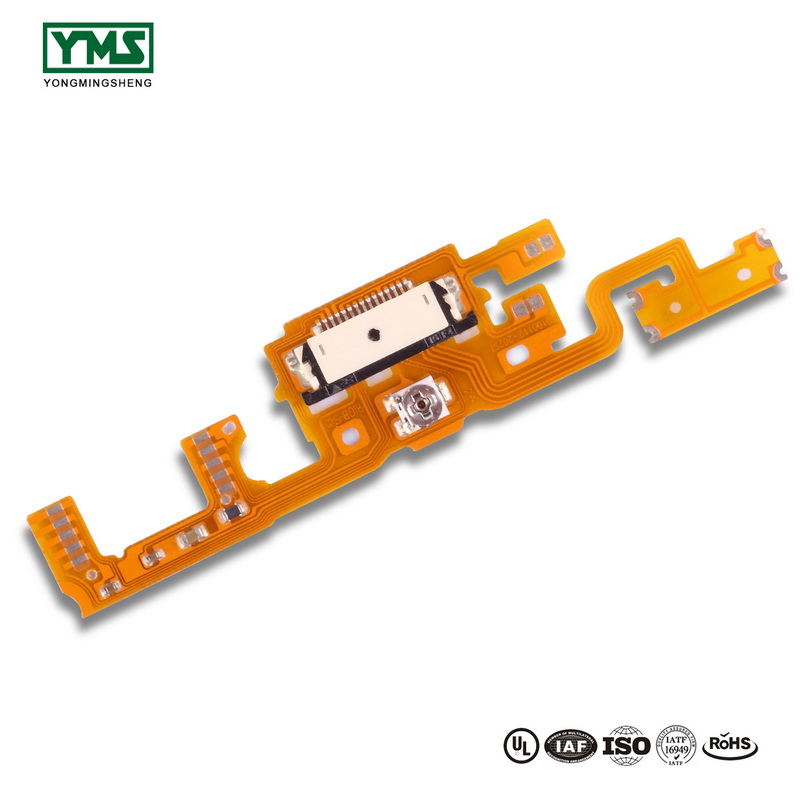

Product detail pictures:

Related Product Guide:

Cop Cracks Crooks’ Copper Caper | 1.2m 2layer Led Pcb

Global Laser Direct Imaging (LDI) System Market Insights 2019-2026: Top Manufacturer Orbotech, ORC Manufacturing, Fuji Film, SCREEN Holdings | Hdi Pcb

We normally believe that one's character decides products' quality, the details decides products' high-quality ,while using the REALISTIC,EFFICIENT AND INNOVATIVE staff spirit for Factory best selling Double Side Metal Core Pcb - Copper Base High Power (Metal core) Board | YMS PCB – Yongmingsheng , The product will supply to all over the world, such as: British, Nicaragua, Costa rica, Immediate and expert after-sale service supplied by our consultant group has happy our buyers. Comprehensive Info and parameters from the merchandise will probably be sent to you for any comprehensive acknowledge. Free samples may be delivered and company check out to our corporation. n Morocco for negotiation is constantly welcome. Hope to get inquiries type you and construct a long-term co-operation partnership.

Product variety is complete, good quality and inexpensive, the delivery is fast and transport is security, very good, we are happy to cooperate with a reputable company!

Write your message here and send it to us