Double sided pcb Normal pcb Lead free HASL Counterbore Manufacturer | YMS PCB

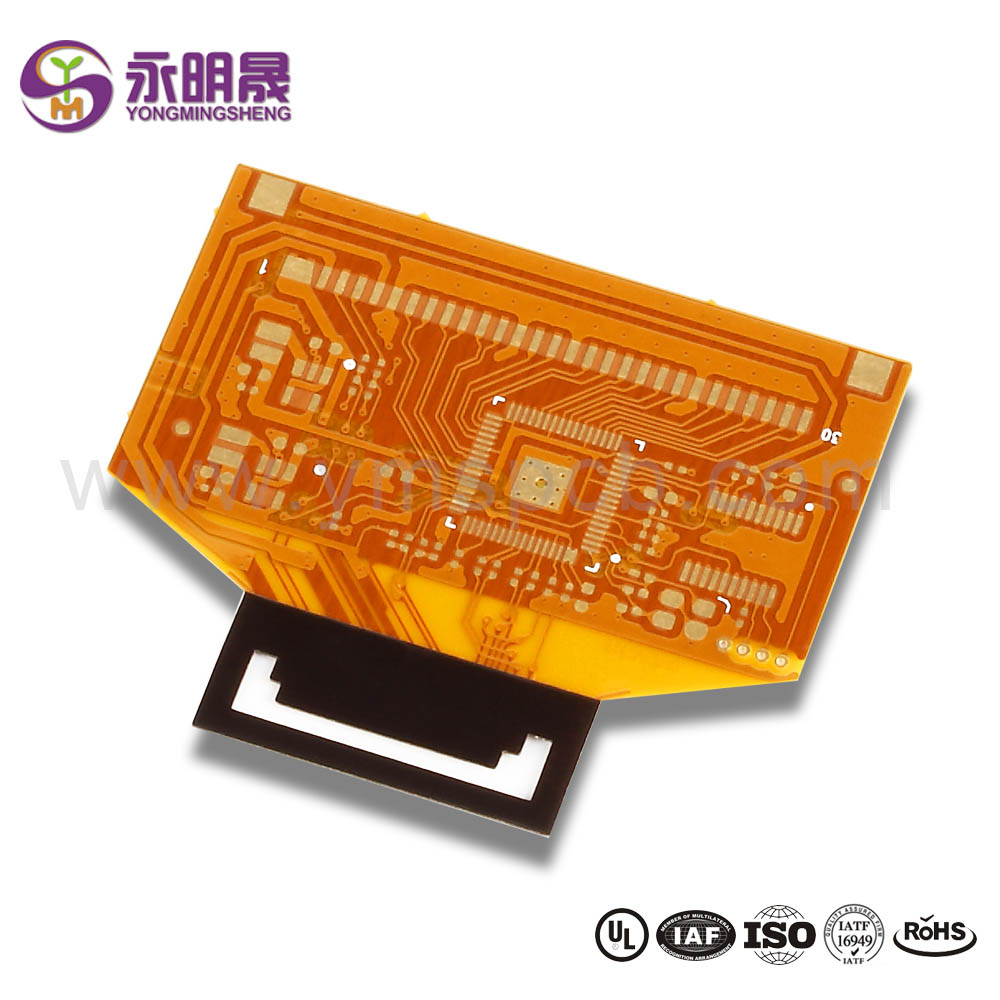

HAL(Lead Free), the full name is Hot Air leveling with Lead Free. Compared with HASL, the main difference for HAL(Lead Free) is the element of material which do not contain Lead(Pb), so it’s RoHS Compliant and it’s much more popular and widely used in trükkplaatide tootmise .

HAL(Lead Free) requires higher run temperatures for lead free solder and longer contact time, the production cost for HAL(Lead Free) is slightly higher than HASL(Tin/Lead).

The manufacturing process of HAL(Lead Free) is similar to HASL(Tin/Lead), the circuit boards will be submersed in molten solder(Lead Free). This solder will cover all the exposed copper surfaces. Upon retraction from the solder, high pressure hot air is blown over the surface through air knives, this levels the solder deposit and removes the excess solder from the surface of printed circuit boards.

Trükkplaadi sissejuhatus

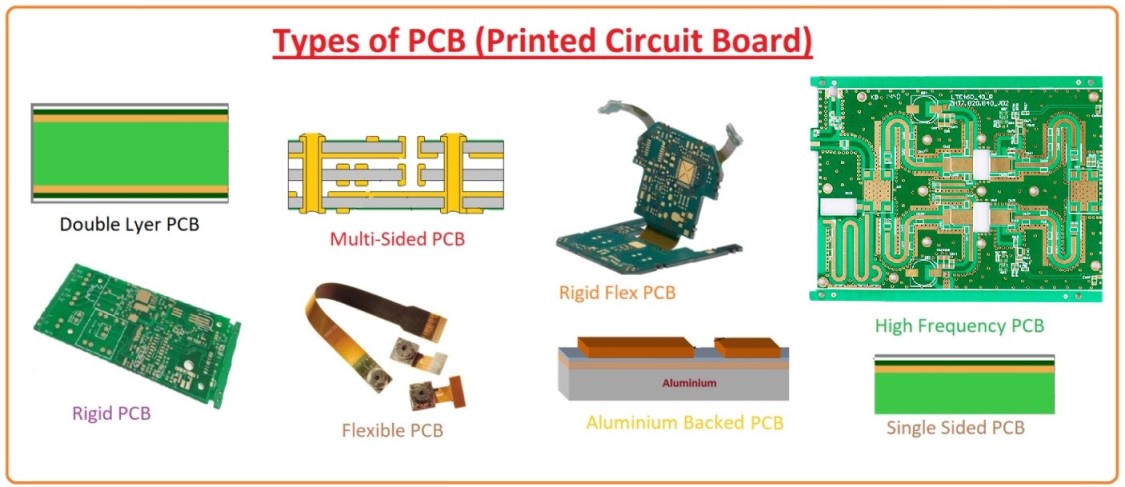

Tavaline trükkplaat: Most PCBs for simple electronics are simple and composed of only a single layer. More sophisticated hardware such as computer graphics cards or motherboards can have 2 or multiple layers, sometimes up to twelve.

A printed circuit board (PCB) mechanically supports and electrically connects electrical or electronic components using conductive tracks, pads and other features etched from one or more sheet layers of copper laminated onto and/or between sheet layers of a non-conductive substrate. Components are generally soldered onto the PCB to both electrically connect and mechanically fasten them to it.PCBs can be single-sided (one copper layer), double-sided (two copper layers on both sides of one substrate layer), or multi-layer (outer and inner layers of copper, alternating with layers of substrate). Multi-layer PCBs allow for much higher component density, because circuit traces on the inner layers would otherwise take up surface space between components. The rise in popularity of multilayer PCBs with more than two, and especially with more than four, copper planes was concurrent with the adoption of surface mount technology.

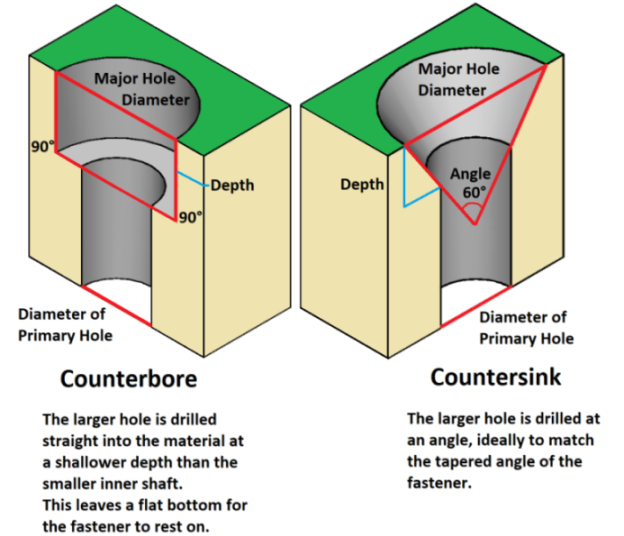

What is the difference between a Countersink and a Counterbore?

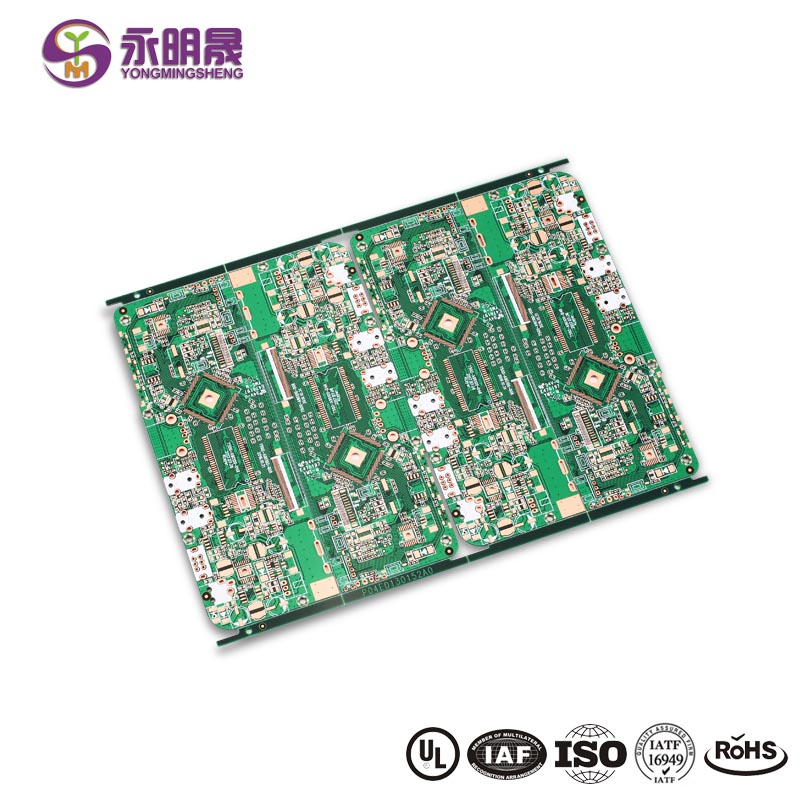

YMS tavalised PCB tootmise võimalused:

| YMS Tavalise PCB tootmise võimaluste ülevaade | ||

| Tunnusjoon | võimeid | |

| Kihtide arv | 1-60L | |

| Saadaval tavaline trükkplaatide tehnoloogia | Läbi ava kuvasuhtega 16: 1 | |

| maetud ja pime via | ||

| Hübriid | Kõrge sagedusega materjal nagu RO4350B ja FR4 Mix jne | |

| Kiire materjal nagu M7NE ja FR4 Mix jne | ||

| Materjal | CEM- | CEM-1; CEM-2, CEM-4, CEM-5.jne |

| FR4 | EM827, 370HR, S1000-2, IT180A, IT158, S1000 / S1155, R1566W, EM285, TU862HF, NP170G jne. | |

| high Speed | Megtron6, Megtron4, Megtron7, TU872SLK, FR408HR, N4000-13 seeria, MW4000, MW2000, TU933 jne. | |

| Kõrgsagedus | Ro3003, Ro3006, Ro4350B, Ro4360G2, Ro4835, CLTE, Genclad, RF35, FastRise27 jne. | |

| Teised | Polüimiid, Tk, LCP, BT, C-kiht, Fradflex, Omega, ZBC2000, PEEK, PTFE, keraamiline baas jne. | |

| Paksus | 0,3–8 mm | |

| Max vase paksus | 10 OZ | |

| Minimaalne joone laius ja ruum | 0.05mm / 0.05mm (2mil / 2mil) | |

| BGA PITCH | 0,35 mm | |

| Min mehaaniline puuritud suurus | 0,15 mm (6 miljonit) | |

| Läbivaava kuvasuhe | 16 : 1 | |

| Pinna viimistlus | HASL, pliivaba HASL, ENIG, keelekümblusplekk, OSP, sukeldushõbe, kuldsõrm, kõvakuldne galvaniseerimine, valikuline OSP , ENEPIG.etc. | |

| Täitmisvõimaluse kaudu | Läbi viaad plaaditakse ja täidetakse juhtiva või mittejuhtiva epoksüga, seejärel kaetakse ja kaetakse plaatidega (VIPPO) | |

| Vasega täidetud, hõbedaga täidetud | ||

| Registreerimine | ± 4mil | |

| Jootemask | Roheline, punane, kollane, sinine, valge, must, lilla, matt must, matt roheline jne. | |

Teile võib meeldida:

1、Summary of matters needing attention in circuit board welding

3 、What is PCB

4、Mis on tühja laua testimine?

Lisateave YMS -toodete kohta