Flex rigid Board semi flex PCB Black Soldermask| YMSPCB

What is Semi-Flex PCB?

Y broses weithgynhyrchu fwyaf traddodiadol o PCB lled-fflecs yw mabwysiadu'r deunyddiau FR-4 plygu a gwneud PCB yn ôl y broses weithgynhyrchu PCB anhyblyg draddodiadol, ac yna defnyddio'r dechnoleg melino dwfn i deneuo'r ardaloedd y mae angen eu plygu fel ei fod wedi rhywfaint o hyblygrwydd, er mwyn cwrdd â gofynion cysylltiad plygu cynulliad.

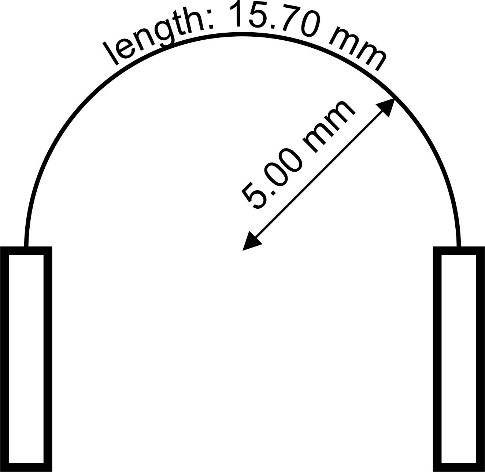

Cyfrifiannell hyd SEMI-FLEX: (radiws plygu 2 x Π x) x (ongl blygu / 360 °)

Er enghraifft, mae plygu 5 gwaith dros ongl o 180 gradd gyda radiws o 5mm yn gofyn am isafswm hyd y rhan lled-fflecs o 15,7mm

YMS Semi-Flex PCB gweithgynhyrchu capa :

| Trosolwg o alluoedd gweithgynhyrchu PCB Semi-Flex YMS | ||

| Nodwedd | galluoedd | |

| Cyfrif Haen | 2-20L , gyda 1 - 2 haen dargludol yn yr adran hyblyg | |

| Trwch anhyblyg-fflecs | 0.5mm-5.0mm | |

| Trwch PCB yn yr adran fflecs | 0.15-0.8mm ± 0.05mm | |

| Trwch copr | 1 / 4OZ-10OZ | |

| Lled a Gofod Isafswm y llinell | 0.05mm / 0.05mm (2mil / 2mil) | |

| Stiffeners | Dur gwrthstaen , PI , FR4 , Alwminiwm ac ati. | |

| Deunydd | FR4, copr RA, copr HTE, gludiog, gorchudd gorchudd Bondply,, flex soldermask | |

| Maint Drilio Min mecanyddol | 0.15mm (6mil) | |

| Maint Tyllau laser Maint: | 0.075mm (3mil) | |

| Gorffen Arwyneb | Gorffeniadau urface Microdon / RF PCB addas: Nickel Electroless, Aur Trochi, ENEPIG, HASL di-blwm, Trochi Arian.etc. | |

| Mwgwd solder | Gwyrdd, Coch, Melyn, Glas, Gwyn, Du, Porffor, Du Matte, Matte green.etc. | |

| Covrelay (Rhan Flex) | Coverlay Melyn, WhiteCoverlay, Black Coverlay |

|

Dysgwch fwy am gynhyrchion YMS

Darllenwch fwy o newyddion

What is a rigid flex board?

The rigid-flex board is a flexible circuit board(FPC) and a rigid circuit board (PCB), which are combined together according to the relevant process requirements through pressing and other processes in the PCB proofing to form a circuit board with FPC characteristics and PCB characteristics.

What is difference between rigid and flexible boards?

As the names suggest, a rigid PCB is a circuit board built on a rigid base layer that cannot bend, while a flexible PCB, also called a flex circuit, is built on a flexible base capable of bending, twisting and folding.

Where are rigid flex PCBs used?

You’ll find them in commercial, industrial and military applications. From digital cameras to cell phones to smart devices, they serve them all. Especially in the medical industry for developing pacemakers for their weight reduction, space, and flexible capabilities.