Chinese wholesale OEM ODM China Pcba Board Pcb, Les Paul Guitar Electric

We know that we only thrive if we can guarantee our combined price tag competiveness and top quality advantageous at the same time for Chinese wholesale OEM ODM China Pcba Board Pcb, Les Paul Guitar Electric, We are one of the largest 100% manufacturers in China. Many large trading companies import products from us, so we can give you the best price with the same quality if you are interested in us.

We know that we only thrive if we can guarantee our combined price tag competiveness and top quality advantageous at the same time for , Nowadays our products and solutions sell all over the domestic and abroad thanks for the regular and new customers support. We present high quality product and competitive price, welcome the regular and new customers cooperate with us!

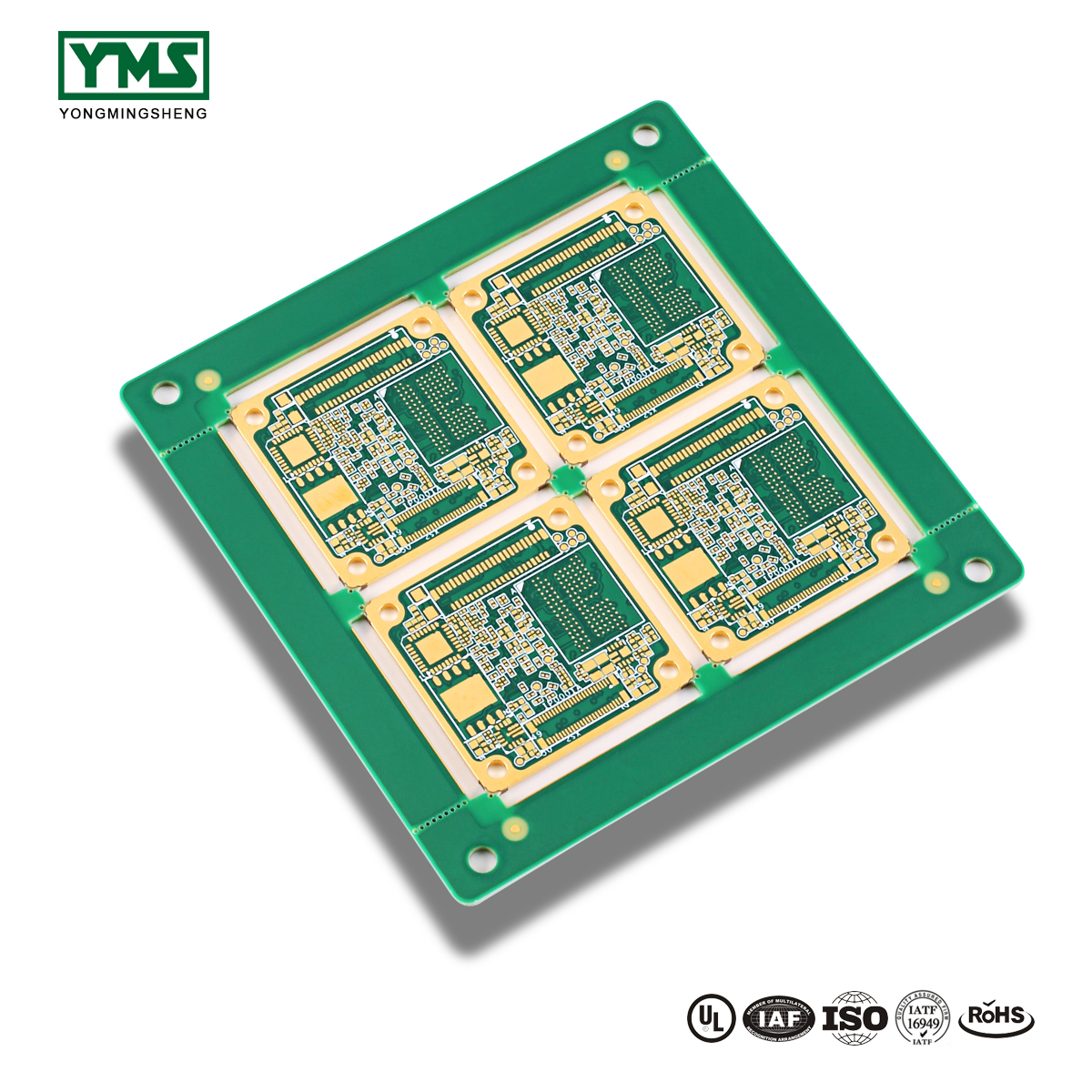

The basic meaning of high Tg circuit board

When the temperature of high Tg printed circuit board rises to a certain threshold, the substrate will change from “glass state” to “rubber state”, and the temperature at this time is called the glass transition temperature (Tg) of the board.

In other words, Tg is the highest temperature (℃) at which the substrate remains rigid.

That is to say, the common PCB substrate material in the high temperature, continuous softening, deformation, melting and other phenomena, but also in the performance of the mechanical and electrical characteristics of the sharp decline, which affects the service life of the product (I think we do not want to see their own products appear in this case).

The main characteristics of high Tg PCB

Generally, Tg plates are above 130℃, high Tg is generally greater than 170℃, and medium Tg is about greater than 150℃.

PCB printed boards with Tg≥170℃ are usually referred to as high Tg printed boards.

With the improvement of Tg of substrate, the heat resistance, moisture resistance, chemical resistance and stability of PCB will be improved.The higher the TG value, the better the temperature resistance of the plate, especially in lead-free process, high TG is more widely used.

Therefore, the difference between general fr-4 and high Tg is as follows: under high temperature, especially under heat after hygroscopicity, the mechanical strength, dimensional stability, adhesion, water absorption, thermal decomposition, thermal expansion and other conditions of the materials are different, and high Tg products are obviously better than ordinary PCB substrate materials.

High TG PCB process capability

Layer: 2-14

Maximum processing area: 640mm*1100mm

Copper thickness: 0.5 OZ – 13 OZ

Plate thickness: double layer plate: 0.2mm–6.0mm

Laminate: 0.4mm-8.0mm 6 laminate: 0.8mm-8.0mm

10 laminate: 1.2mm-8.0mm

12 laminate: 1.5mm-8.0mm 14 laminate: 1.5mm-8.0mm

16 laminate: 1.6mm-8.0mm 18 laminate: 2.2mm-8.0mm

20 laminate: 2.4mm-8.0mm

Minimum line width/spacing: 3mil/3mil

Finished product minimum aperture: 0.15mm

Maximum machined thickness to diameter ratio: 12:1

Impedance control: +/-10%

Surface treatment: spray lead tin, spray pure tin, chemical precipitation gold, chemical precipitation tin, chemical precipitation silver, plug gold-plated, anti-oxidation

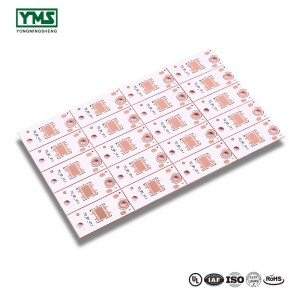

Commonly used sheet: FR4 Tg130 / Tg170 ℃, Rogers, Arlon, Taconic, Bergquist

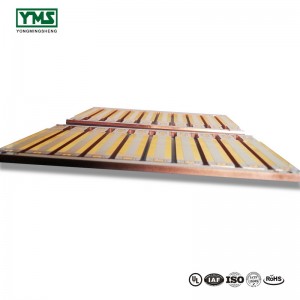

Special process: blind hole burial, plate hole, plate edge metallization, half hole, step mounting hole, deep hole control, metal base (core) plate.

Application of high Tg plate in plate copying

High Tg plank in the application of copy plate at the present stage include: high-precision double-sided PCB PCB copy board, carbon oil filling hole PCB circuit board PCB copy board, high Tg PCB copy board, PCB PCB copy board, thick copper plate plane winding professional copy board, mixed media board PCB copy board, special base board copy board and customize various specific requirements printed circuit board, high Tg in every corner of the plate is widely used in industry.

HDI basic production process:

A、Brown multilayer circuit board to form Browning film on the surface of copper foil layer, and laser drilling on the surface of copper foil to form laser blind hole

B、 drill the multi-layer circuit board to form a mechanical drill hole

C、 The multi-layer circuit board is coated with copper to form a copper layer in the laser blind hole mechanical drilling, and then the multi-layer circuit board is electroplated to thicken the copper layer in the hole

D、The above multilayer circuit board is made of outer graphics, and the surface treatment of etched screen print resistance welding on the outer layer of graphics electroplating is carried out to obtain the finished HDI board

You May Like:

1、How to make high frequency PCB

2、Common knowledge of high frequency PCB wiring (1)

3、Common knowledge of high frequency PCB wiring (2)