Best quality 2layer Alu Core Pcb - HDI printed circuit boards 8Layer 2 Step HDI Board| YMS PCB – Yongmingsheng

Best quality 2layer Alu Core Pcb - HDI printed circuit boards 8Layer 2 Step HDI Board| YMS PCB – Yongmingsheng Detail:

HDI Board production process:

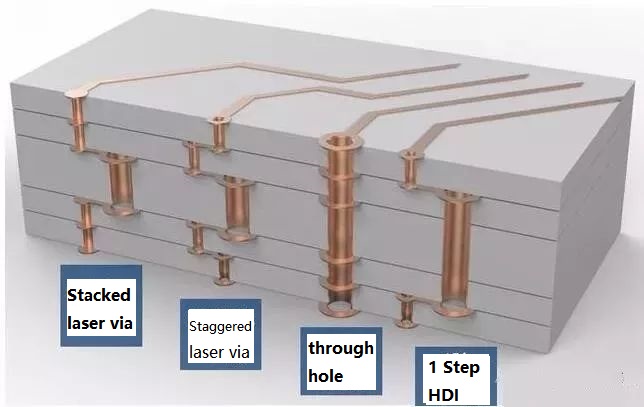

At present, HDI board interconnection between layer and layer is mainly the following design: Staggered holes interconnection, Cross-layer interconnection, ladder interconnection and superposition holes interconnection. Among them, the superposition holes interconnection occupy the least space. There is a research suggests that reducing the number of through holes and increasing the number of blind holes can effectively improve the wiring density. And in the superposition interconnection, the methods of electroplating and resin plug are mainly used, especially the electroplating hole filling method which has more obvious advantages like high reliability and good conduction performance. Therefore, superposition interconnection is the most widely used design method for blind holes design. The process of stacking between layers is as follows: first blind hole is made, then second blind hole is made after lamination, then multi-blind hole is made according to this method, and the interconnection between layers is realized by electroplating hole filling method.

On the whole, the production process of HDI plate is complex, which needs to be completed after many times of production for a long time. It’s not only high requirements for the accuracy and shrinkage control of each layer, but also high standards in materials, equipment, environment and technical personnel.

YMS HDI PCB manufacturing capabilities:

| YMS HDI PCB manufacturing capabilities overview | |

| Feature | capabilities |

| Layer Count | 4-60L |

| Available HDI PCB Technology | 1+N+1 |

| 2+N+2 | |

| 3+N+3 | |

| 4+N+4 | |

| 5+N+5 | |

| Any layer | |

| Thickness | 0.3mm-6mm |

| Minimum line Width and Space | 0.05mm/0.05mm(2mil/2mil) |

| BGA PITCH | 0.35mm |

| Min laser Drilled Size | 0.075mm(3nil) |

| Min mechanical Drilled Size | 0.15mm(6mil) |

| Aspect Ratio for laser hole | 0.9:1 |

| Aspect Ratio for through hole | 16:1 |

| Surface Finish | HASL, Lead free HASL,ENIG,Immersion Tin, OSP, Immersion Silver, Gold Finger, Electroplating Hard Gold, Selective OSP,ENEPIG.etc. |

| Via Fill Option | The via is plated and filled with either conductive or non-conductive epoxy then capped and plated over |

| Copper filled, silver filled | |

| Laser via copper plated shut | |

| Registration | ±4mil |

| Solder Mask | Green, Red, Yellow, Blue, White, Black, Purple, Matte Black, Matte green.etc. |

You May Like:

1、What is the difference between HDI board and ordinary PCB

2、What does the HDI board need to pay attention to

3、What is high density printed circuit board (HDI)

Product detail pictures:

Related Product Guide:

Global HDI Market Analysis, Demand, Size & Forecast 2019-2025: Unimicron, Compeq, AT&S, SEMCO, Ibiden, TTM, ZDT, Tripod, DAP, Unitech, Multek, LG Innotek | Copper Base Board

LDI (Laser Direct Imaging) Machines Market Global Size, Demand-sales, Suppliers by Key Applications 2019 Detailed Analysis and Growth Aspects on Manufacturing Landscapes | Hdi Pcb

To meet the customers' over-expected satisfaction , we have our strong team to provide our best overall service which includes marketing, sales, designing, production, quality controlling, packing, warehousing and logistics for Best quality 2layer Alu Core Pcb - HDI printed circuit boards 8Layer 2 Step HDI Board| YMS PCB – Yongmingsheng , The product will supply to all over the world, such as: Lisbon, Salt Lake City, Bangladesh, During in 11 years, We've participated in more than 20 exhibitions, obtains the highest praise from each customer. Our company has been devoting that "customer first" and committed to helping customers expand their business, so that they become the Big Boss !

Sales manager is very enthusiastic and professional, gave us a great concessions and product quality is very good,thank you very much!