Flex rigid Board semi flex PCB Black Soldermask| YMSPCB

What is Semi-Flex PCB?

Die mees tradisionele vervaardigingsproses van semi-flex PCB is die aanvaarding van die buigende FR-4-materiale en die maak van PCB volgens die tradisionele rigiede PCB-vervaardigingsproses, en dan die diep frees-tegnologie gebruik om die areas wat gebuig moet word, te verdun sodat dit 'n sekere mate van buigsaamheid om aan die vereistes van 'n monteerbuigverbinding te voldoen.

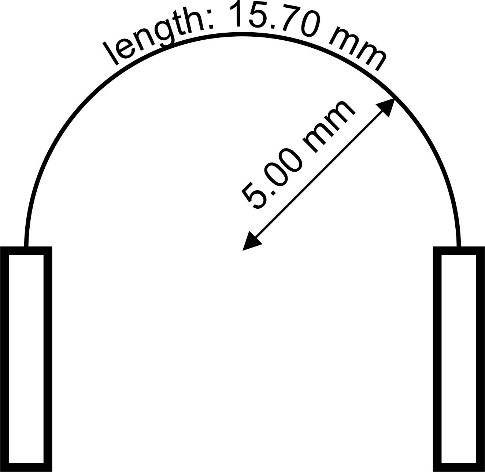

SEMI-FLEX lengte sakrekenaar: (2 x Π x buigstraal) x (bughoek / 360 °)

Om byvoorbeeld 5 keer oor 'n hoek van 180 grade met 'n radius van 5 mm te buig, vereis 'n minimum lengte van die semi-buigsame deel van 15,7 mm

YMS Semi-Flex PCB vervaardigingsvermoë :

| YMS Semi-Flex PCB vervaardigingsvermoë oorsig | ||

| Funksie | vermoëns | |

| Laagtelling | 2-20L , met 1 - 2 geleidende lae in die buigsame gedeelte | |

| Styf-buig dikte | 0.5mm-5.0mm | |

| PCB-dikte in buigsnit | 0.15-0.8mm ± 0.05mm | |

| koper Dikte | 1 / 4OZ-10OZ | |

| Minimum lynbreedte en spasie | 0.05mm / 0.05mm (2mil / 2mil) | |

| Verstyfers | Vlekvrye staal, PI, FR4, Aluminium, ens. | |

| Materiaal | FR4, RA koper, HTE koper, kleefmiddel, Bondply , deklaag, buig soldeermasker | |

| Min meganiese geboorde grootte | 0.15mm (6mil) | |

| Min laser gate: | 0,075 mm (3 miljoen) | |

| Oppervlak afwerking | Geskikte mikrogolf / RF PCB-oppervlakafwerkings: elektrolose nikkel, onderdompelingsgoud, ENEPIG, loodvrye HASL, onderdompeling silwer. Ens. | |

| Soldeermasker | Groen, Rooi, Geel, Blou, Wit, Swart, Pers, Mat Swart, Matgroen. Ens. | |

| Covrelay (Flex Part) | Geel deklaag, wit omslag, swart deklaag |

|

Kom meer te wete oor YMS-produkte

Lees meer nuus

What is a rigid flex board?

The rigid-flex board is a flexible circuit board(FPC) and a rigid circuit board (PCB), which are combined together according to the relevant process requirements through pressing and other processes in the PCB proofing to form a circuit board with FPC characteristics and PCB characteristics.

What is difference between rigid and flexible boards?

As the names suggest, a rigid PCB is a circuit board built on a rigid base layer that cannot bend, while a flexible PCB, also called a flex circuit, is built on a flexible base capable of bending, twisting and folding.

Where are rigid flex PCBs used?

You’ll find them in commercial, industrial and military applications. From digital cameras to cell phones to smart devices, they serve them all. Especially in the medical industry for developing pacemakers for their weight reduction, space, and flexible capabilities.