Flex Rigid PCB PI Stiffener electromagnetic shielding film| YMS PCB

Applications:

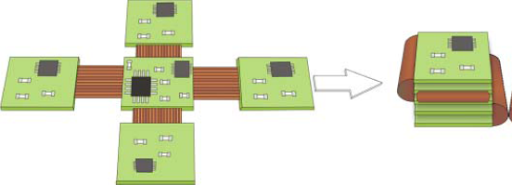

As the name implies, rigid-flex printed circuit boards(PCBs) are the composite boards of rigid boards and flexible boards. Most rigid-flex circuits are multi-layered. A rigid-flex PCB can include one/several flex boards and rigid boards, which are connected through internally/externally plated-through holes.

Rigid Flexible PCB: Bend radius controls the flexibility of the flex portion of the board. The thinner the material the lower the bend radius and the more flexible the flex section.

Rigid flexible PCBs offer a wide range of applications, from military weapons and aerospace systems to mobile phones and digital cameras. Rigid flexible plate manufacturing is increasingly used in medical devices, such as pacemakers, to gain space and the ability to reduce weight. The use of rigid flexible PCBS also has advantages that can be used in military weapons and weapon control systems in consumer products.

Parameters

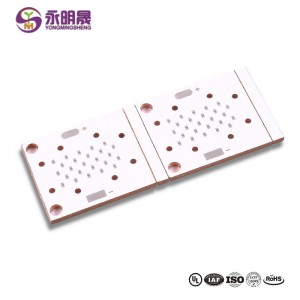

Layers: 4L Rigid flex PCBs with PI Stiffener

Board Thinkness:0.8mm+/-0.1mm

PCB thickness in flex section:0.1mm+/-0.03mm

Base Material:PI+FR4

Min mechanical Holes:0.2mm

Minimum Line Width/Clearance:0.1mm/0.1mm(4mil/4mil)

Minimum Clearance between Inner Layer PTH and Line: 0.2mm

Size:150mm×20mm

Aspect Ratio:4 : 1

Surface treatment:OSP

Speciality: Rigid flex pcb core+core stackup,PI Stiffener,With the structure of electromagnetic shielding film

Differential impedance 100+7/-8Ω

Applications: Consumer electronics

Flexibility:

Rigid flexibility not only maximizes space and weight but also greatly improves reliability, eliminating the need for many welded joints and weak wires that can easily create connection problems. These are just a few examples, but rigid flexible PCBS can be used in almost all advanced electrical applications, including test equipment, tools, and automobiles. Besides the benefits mentioned above, other common advantages of rigid-flex PCBs include high circuit density, excellent thermal dissipation and chemical resistance, etc. All in all, rigid-flex PCBs combine all the benefits of hard PCB and flexible PCB while complementing the disadvantages.

This kind of PCB is an optimal solution to design reliable and robust circuits for smart wearable devices and other industries. YMS has a strict quality control system to ensure the rigid-flex boards manufactured and assembled correctly with high-quality standards.

If you need more details like quotation or order, contact us kell@ymspcb.com now.

Rigid-flex PCBs introduction:

As the name implies, rigid-flex printed circuit boards(PCBs) are the composite boards of rigid boards and flexible boards. Most rigid-flex circuits are multi-layered. A rigid-flex PCB can include one/several flex boards and rigid boards, which are connected through internally/externally plated-through holes.

YMS Rigid Flex PCB manufacturing capabilities:

| YMS Rigid Flex PCB manufacturing capabilities overview | ||

| Feature | capabilities | |

| Layer Count | 2-20L | |

| Rigid-Flex Thickness | 0.3mm-5.0mm | |

| PCB thickness in flex section | 0.08-0.8mm | |

| copper Thickness | 1/4OZ-10OZ | |

| Minimum line Width and Space | 0.05mm/0.05mm(2mil/2mil) | |

| Stiffeners | Stainless steel,PI, FR4 ,Aluminum etc. | |

| Material | Polyimide Flex+FR4,RA copper, HTE copper, polyimide, adhesive,Bondply | |

| Min mechanical Drilled Size | 0.15mm(6mil) | |

| Min laser Holes Size: | 0.075mm(3mil) | |

| Surface Finish | Suitable Microwave/RF PCB urface finishes: Electroless Nickel, Immersion Gold, ENEPIG, Lead free HASL,Immersion Silver.etc. | |

| Solder Mask | Green, Red, Yellow, Blue, White, Black, Purple, Matte Black, Matte green.etc. | |

| Covrelay (Flex Part) | Yellow Coverlay, WhiteCoverlay,Black Coverlay | |

| Common-Used FPC Stiffener Thickness | ||

| Stiffener Material | Usual Thickness | Unusual Thickness |

| FR-4 | 0.2mm(8mil) | 0.1mm(4mil) |

| 0.3mm(12mil) | 0.9mm(35mil) | |

| 0.4mm(16mil) | 1.1mm(43mil) | |

| 0.5mm(20mil) | 1.3mm(51mil) | |

| 0.6mm(24mil) | 1.4mm(55mil) | |

| 0.7mm(28mil) | 1.6mm(63mil) | |

| 0.8mm(32mil) | ||

| 1.0mm(39mil) | ||

| 1.2mm(47mil) | ||

| 1.5mm(59mil) | ||

| Polyimide (PI) | 0.1mm(4mil), | 0.075mm(3mil) |

| 0.15mm(6mil), | 0.125mm(5mil) | |

| 0.2mm(8mil), | 0.175mm(7mil) | |

| 0.25mm(10mil) | 0.225mm(9mil) | |

| 0.275mm(11mil) | ||

| Stainless Steel | 0.1mm(4mil) | 0.45mm(18mil) |

| 0.15mm(6mil) | ||

| 0.2mm(8mil) | ||

| 0.25mm(10mil) | ||

| 0.3mm(12mil) | ||

| 0.35mm(mil) | ||

| 0.4mm(16mil) | ||

| 0.5mm(20mil) | ||

| 1.5mm(59mil) | ||

Read more news

What is rigid flex PCB?

Rigid flex printed circuit boards are boards using a combination of flexible and rigid board technologies in an application.

What are rigid flex PCBs used for?

Rigid-flex PCBs are freedom in packaging geometry and can be tailored for applications in many industries such as aerospace, military, medical equipment, and consumer electrics. They are available to customize the size and shape to fit the housing designs and 3D designs, which provides designers more possibilities to meet different requirements in specific applications.

What is a flex PCB?

Flexible PCBs (FPC) are the PCBs that can be bent or twisted without damaging the circuits, which means the boards can be bent freely to conform to the desired shape during applications. The material the substrate used is flexible, such as Polyamide, PEEK, or a conductive polyester film.

What is difference between rigid and flexible boards?

As the names suggest, a rigid PCB is a circuit board built on a rigid base layer that cannot bend, while a flexible PCB, also called a flex circuit, is built on a flexible base capable of bending, twisting and folding.

What is flex PCB material?

While most standard PCBs have a fiberglass or metal base, flex circuit cores consist of a flexible polymer.