Flex PCB Prototyping 1Layer White Solder Mask | YMSPCB

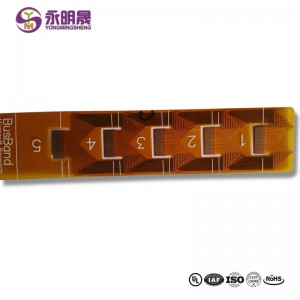

There is a layer of solder mask on both sides of a rigid PCB. The solder mask has gaps, and the SMT pads or PTH holes are exposed to allow components to assemble. FPC usually uses a cover coat instead of a solder mask. ridge PCB usually has a green or blue or black solder mask, but overlay only has yellow. The overlay is a thin polyimide material that can be drilled or laser-cut to access the components. There are no mechanical connectors in FPC applications, which improves durability in harsh environments. And the heat dissipation ability of FPCs is better than rigid PCBs. Therefore, flexible PCBs can be found in many computer components, televisions, printers, and gaming systems.

Flexible PCBs have so many unique advantages in various applications, while they still cannot replace rigid PCBs. YMS is an experienced PCB manufacturer that provides turnkey service for PCB assembly prototypes and small-batch PCB fabrication. Please contact us if you need more details or other help.

Application of FPC

1. Computer and External Equipment: HDD, laptop, transmission line, printer, scanner, keyboard, etc.

2. Communication and Office Equipment: cell phone, photocopier, fiber-optic switch, laser communication device, etc.

3. Communication Electronic Equipment: camera, CVCR, LCD with plasma TV, etc.

4. Automotive: display instrument, ignition and break switch system, exhaust controller, anti-lock brake system, Onboard mobile phones and satellite positioning systems, etc.

5. Industrial Instruments and Equipment: sensor, electronic device, nuclear magnetic analyzer, X-ray, laser or infrared light control instrument and electronic weighing apparatus, etc.

6. Medical Equipment: cardiac pacemaker, endoscope, digital signal processing hearing aid, ultrasonic therapy instrument, nerve activation device, diagnostic equipment and program controller, etc

7. Aerospace and Military: satellite, spacecraft, rocket and missile controllers, remote sensing and telemetry devices, radar systems, navigation devices, gyroscopes, spy reconnaissance equipment, anti-tank rocket weapons, etc

8. Integrated Circuit: IC sealing and loading board, IC magnetic card core board, etc

Learn more about YMS products

What is flex PCB board?

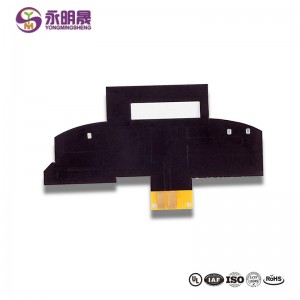

Flexible PCBs (FPC) are PCBs that can be bent or twisted without damaging the circuits, which means the boards can bend freely to conform to the desired shape in the applications. The material of the substrate is flexible, such as Polyamide, PEEK, or a conductive polyester film.

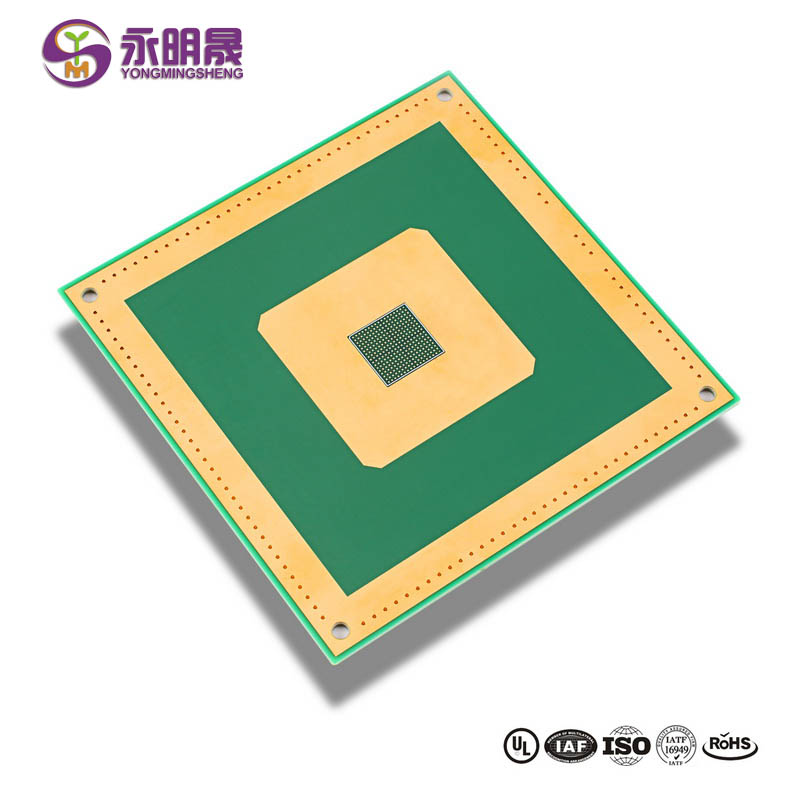

What is a rigid flex PCB?

As the name implies, rigid-flex printed circuit boards(PCBs) are the composite boards of rigid boards and flexible boards. Most rigid-flex circuits are multi-layered. A rigid-flex PCB can include one/several flex boards and rigid boards, which are connected through internally/externally plated-through holes.

How do I make my PCB flexible?

a flexible pcb must have coverlay+polyimide+stiffener

How thick is a flex PCB?

0.08~0.4mm+