Aluminum base pcb aluminum substrate pcb 1Layer Aluminum base Board| YMSPCB

Applications of Aluminum PCB

Aluminum PCB is one of the most widely used metal core PCBs, also called as MC PCB, aluminum-clad, or insulated metal substrate, etc. It features a thermal clad layer that dissipates heat in a highly efficient manner while cooling components and increasing the overall performance of the products. Currently, Aluminum Backed PCB is regarded as the solution to high power and tight tolerance applications

1. Better temperature management

As we all know, high-temperature situations will appear when the electronics are operating at high speeds. If the thermal energy cannot be directed away quickly, the components which under high temperature may be softened, deformation, parameters changed, and performance changed, even present safety risks. Aluminum bases can remove the heat from components very soon, which allows high-density and high-power PCB designs to be achieved. The heat dissipation efficiency of aluminum PCB is ten times higher than the fiber-glass base PCBs.

2. Excellent mechanical stability and lighter weight

Substrates made of aluminum alloys have high physical durability, which can reduce the risk of breakage during transportation and daily use. And aluminum is a lighter metal. It can provide greater strength and flexibility than other metal PCBs with equal weight.

3. Reasonable cost with lower environmental impact

Aluminum is cheaper and eco-friendlier compared to other metal bases because it is a non-toxic metal and easy to extract. And less additional radiators are needed when the components that have high requirements for thermal dissipation assembled on aluminum board. It means there is less manufacturing and material cost when using aluminum PCBs.

The applications and types of aluminum PCBs

The best benefit of aluminum PCB is the excellent efficiency of heat dissipation. It transmits the heat and cools the components fast, which can improve the overall performance of the end products. Therefore, aluminum PCBs are the ideal solution for high-density and high-power products such as LED applications, power supply equipment, computers, and so on.

YMS Aluminum PCB manufacturing capabilities:

| YMS Aluminum PCB manufacturing capabilities overview | ||

| Feature | capabilities | |

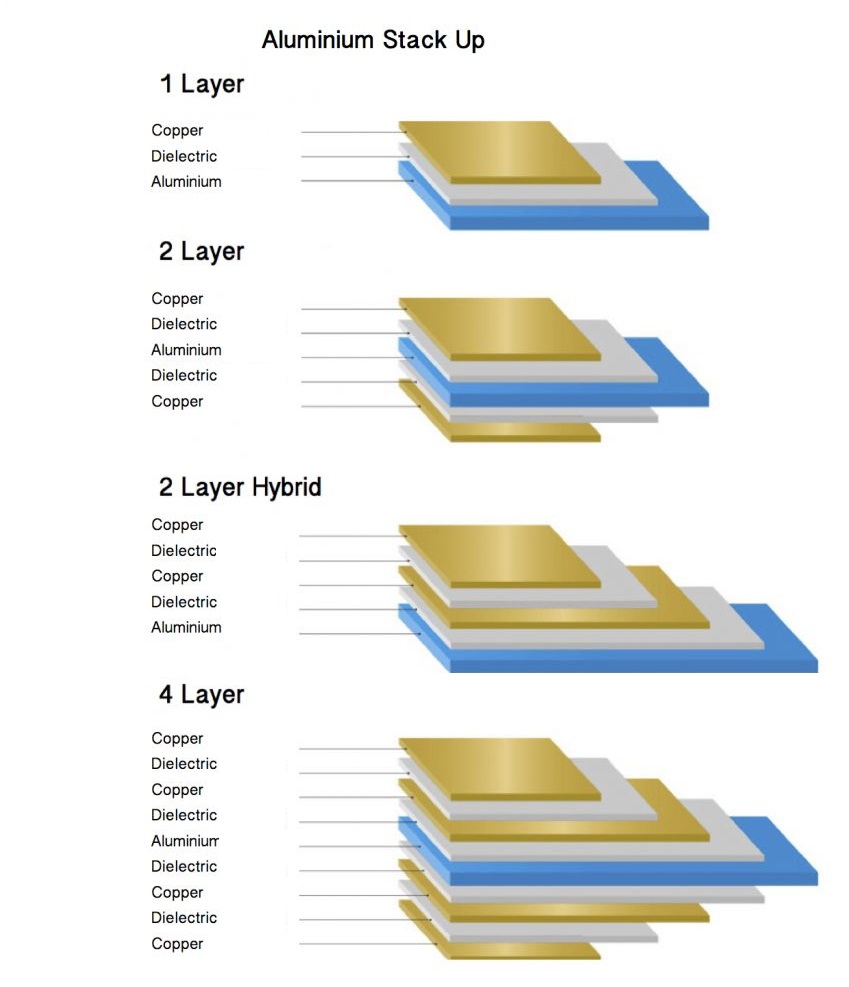

| Layer Count | 1-4L | |

| Thermal Conductivity(w/m.k) | Aluminum PCB:0.8-10 | |

| Copper PCB:2.0-398 | ||

| Board Thickness | 0.4mm-5.0mm | |

| copper Thickness | 0.5-10OZ | |

| Minimum line Width and Space | 0.1mm/0.1mm(4mil/4mil) | |

| Speciality | Countersink,Counterbore drilling.etc. | |

| Types of Aluminum Substrates | 1000 series;5000 series;6000 series,3000 series.etc. | |

| Min mechanical Drilled Size | 0.2mm(8mil) | |

| Surface Finish | HASL, Lead free HASL,ENIG,Immersion Tin, OSP, Immersion Silver, Gold Finger, Electroplating Hard Gold, Selective OSP,ENEPIG.etc. | |

| Solder Mask | Green, Red, Yellow, Blue, White, Black, Purple, Matte Black, Matte green.etc. | |

Learn more about YMS products

Video

What is an aluminum PCB?

Aluminum PCB is the most common type. The base material consists of an aluminum core and standard FR4

What are aluminum PCBs used for?

Audio device;Communication electronic equipment;Power Modules;Lamps and lighting

What are the 3 types of PCB?

Rigid PCB;flex;Rigid-flex

What metal is PCB made of?

NA

Board3-300x300.jpg)